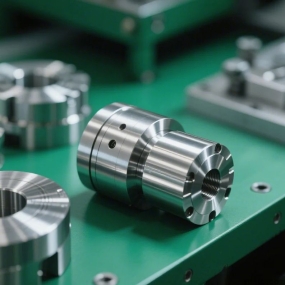

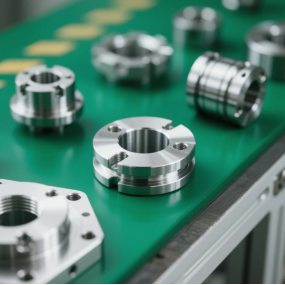

In the realm of high-precision manufacturing, CNC stainless steel precision machining stands as a cornerstone for industries demanding exceptional durability, corrosion resistance, and dimensional accuracy. At EMAR, we specialize in delivering cutting-edge CNC Machining solutions tailored to meet the stringent requirements of aerospace, medical, automotive, and industrial applications.

Why Choose CNC Machining for Stainless Steel Components?

Stainless steel's inherent properties—high strength, heat resistance, and hygienic surface—make it ideal for critical applications. Our CNC stainless steel precision machining process leverages multi-axis CNC mills and lathes equipped with advanced tooling to achieve tolerances as tight as ±.005mm. This ensures seamless compatibility with assemblies while minimizing post-processing needs.

EMAR's Technical Capabilities

Our facility houses state-of-the-art 5-axis CNC machines capable of handling complex geometries in grades like 304, 316, and 17-4PH stainless steel. Key advantages include:

- Mirror finishes (Ra ≤.2μm) achieved through precision grinding and polishing

- Thread milling for high-strength fastening applications

- Micro-machining capabilities for medical implants and miniature components

Industry-Specific Solutions

For medical device manufacturers, we offer CNC stainless steel precision machining with full traceability and biocompatibility certifications. In the energy sector, our machined components withstand extreme pressures and corrosive environments. Every project undergoes rigorous QA checks, including CMM verification and material composition testing.

Explore how EMAR's CNC machining expertise can optimize your stainless steel components—visit www.sjt-ic.com to request a free DFM analysis today.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque