As a leading CNC Machining service provider, EMAR specializes in manufacturing high-precision kitchenware components for commercial and residential applications. This article will explain the complete technical process of producing kitchenware parts through CNC machining.

Material Selection for Kitchenware Components

The process begins with selecting food-grade materials that meet hygiene and durability requirements. We typically use 304/316 stainless steel, food-safe aluminum alloys, or engineering plastics like PEEK. Our material certification process ensures traceability and compliance with international food safety standards.

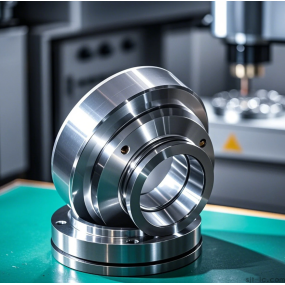

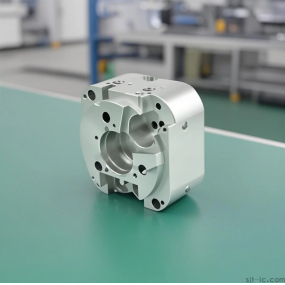

CNC Machining Techniques

Our 5-axis CNC machines achieve ±.01mm precision for complex kitchenware parts like burner caps, knife fittings, and mixer components. Advanced toolpath programming optimizes surface finishes while maintaining tight tolerances. We employ special coolant systems to prevent material contamination during machining.

Surface Treatment Options

Post-machining treatments include:

Electropolishing for stainless steel parts

Anodizing for aluminum components

Food-grade powder coating

These processes enhance corrosion resistance and meet NSF/ISO food contact requirements.

Quality Assurance Protocol

Every batch undergoes:

3D scanning for dimensional verification

Material composition testing

Surface roughness measurement

Functional testing under simulated conditions

Our ISO 9001-certified quality system ensures consistent performance.

EMAR's CNC machining capabilities deliver kitchenware parts with exceptional precision, durability, and food safety compliance. Contact our engineering team at www.sjt-ic.com for custom solutions tailored to your specific requirements.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque