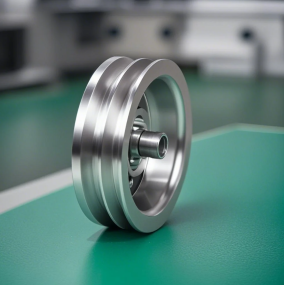

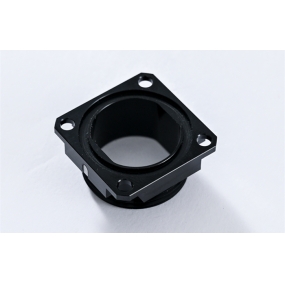

As a premier CNC Machining service provider, EMAR specializes in manufacturing precision gearbox components for industrial applications. Our advanced CNC technology ensures exceptional dimensional accuracy and surface finish for critical transmission parts.

Why Choose CNC Machining for Gearbox Components?

Gearbox systems demand components with tight tolerances (typically ±.01mm) and superior wear resistance. Our 5-axis CNC machining centers produce:

Precision gears with involute tooth profiles

High-load bearing housings

Complex shaft assemblies

Worm gear sets with optimized backlash

Material Selection for Durability

We machine gearbox components from various materials including alloy steels (414, 434), stainless steels (303, 304), and aluminum alloys (6061, 7075), all heat-treated for enhanced mechanical properties.

EMAR's Technical Advantages

Our ISO 9001-certified facility features:

Swiss-type CNC lathes for micro-precision parts

Multi-pallet machining centers for batch production

CMM inspection (.001mm repeatability)

Surface treatments: nitriding, carburizing, or DLC coating

With 15+ years of experience in transmission system manufacturing, EMAR delivers reliable CNC machining solutions that meet AGMA, ISO, and DIN standards. Contact our engineering team at www.sjt-ic.com for customized gearbox component solutions.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque