When it comes to red copper CNC Machining, EMAR stands as a trusted partner for industries demanding exceptional conductivity, corrosion resistance, and intricate metal components. Our advanced CNC technology ensures micron-level accuracy for your copper parts, whether for electrical, automotive, or industrial applications.

Why Choose Red Copper for CNC Machining?

Red copper (C11000) offers superior electrical/thermal conductivity and ductility, making it ideal for busbars, connectors, and heat exchangers. However, its softness requires specialized CNC machining expertise to prevent deformation – a challenge EMAR overcomes through:

Rigid machine tools with high-speed spindles (up to 30,000 RPM)

Custom fixturing solutions to minimize vibration

Optimized tool paths using Mastercam programming

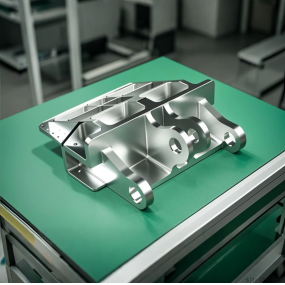

EMAR's Precision Machining Capabilities

Our 5-axis CNC centers deliver ±.005mm tolerances for complex copper geometries. We combine red copper machining with secondary processes including:

Deburring and edge radiusing

Passivation for oxidation resistance

Plating (tin, silver, or nickel options)

Industry-Specific Applications

From EV battery components to RF waveguide parts, our copper machining serves:

Electronics: EMI shielding enclosures, heat sinks

Energy: Transformer windings, solar collector parts

Medical: Sterilizable surgical instrument components

With ISO 9001-certified quality control and 24/7 project support, EMAR delivers copper parts that meet MIL-STD and ASTM standards. Request a quote for your custom red copper machining project today.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque