As a CNC Machining expert at EMAR (https://www.sjt-ic.com/), I understand that cost efficiency is a top priority for procurement managers and engineers sourcing CNC aluminum parts processing services. This article reveals key factors affecting pricing and how our company delivers premium yet affordable solutions.

Understanding Pricing Factors in CNC Aluminum Machining

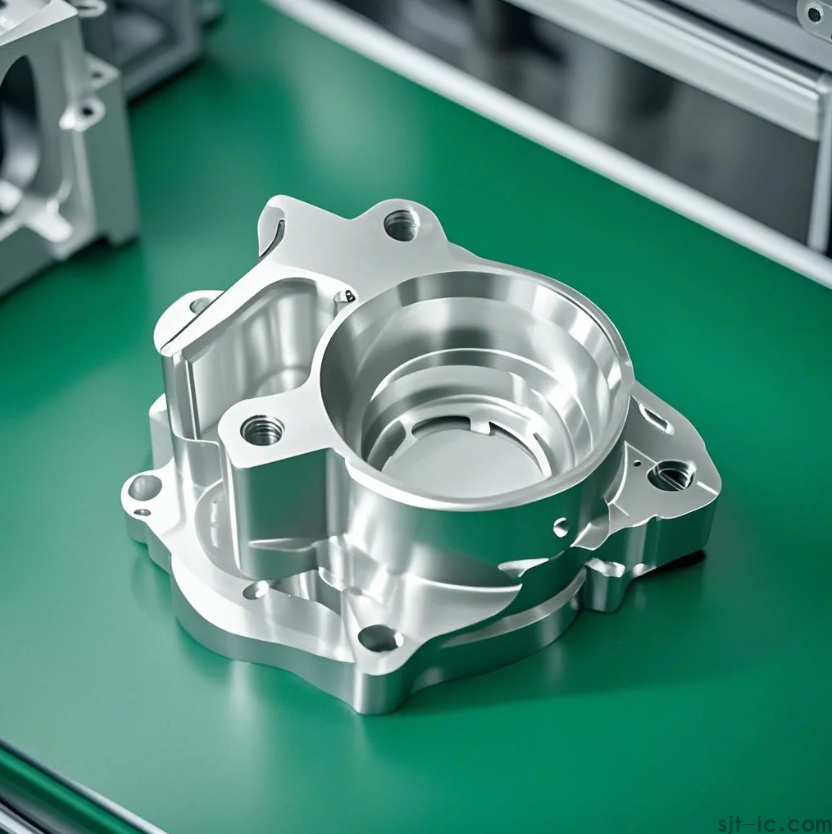

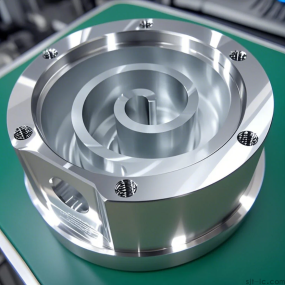

The cost of CNC aluminum parts processing depends on material grade (6061 vs 7075), part complexity, batch size, and secondary operations. EMAR optimizes all variables through:

Advanced 5-axis machines reducing setup time

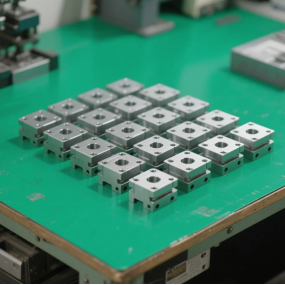

Bulk material purchasing discounts

Automated finishing processes

Why EMAR Offers Competitive CNC Aluminum Processing

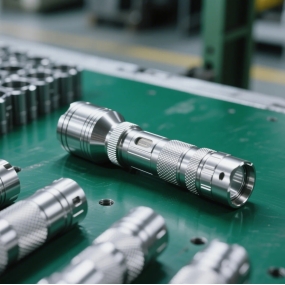

Our Shenzhen-based facility combines China's manufacturing advantages with German-level precision:

ISO 9001-certified CNC machining processes

30% lower operational costs than Western counterparts

Direct factory pricing without middlemen

Balancing Cost and Quality in Aluminum CNC Work

While seeking affordable solutions, never compromise on:

Material traceability certificates

First-article inspection reports

Surface finish consistency (Ra .8μm achievable)

EMAR provides free DFM analysis to help optimize your aluminum part designs for both performance and cost-efficiency. Contact our engineering team today for a transparent quotation.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque