In the highly regulated medical industry, precision and reliability are non-negotiable. CNC medical parts machining plays a critical role in producing components that meet stringent quality standards while ensuring patient safety.

Why Choose CNC Machining for Medical Components?

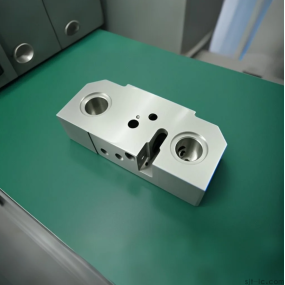

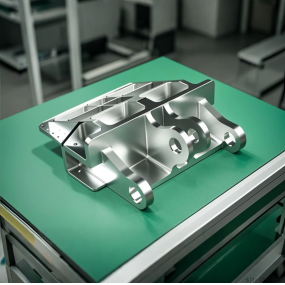

Medical devices demand exceptional accuracy, often with tolerances within ±.001 inches. Our CNC machining capabilities at EMAR enable us to manufacture complex geometries from biocompatible materials like titanium, stainless steel, and medical-grade plastics. The process ensures:

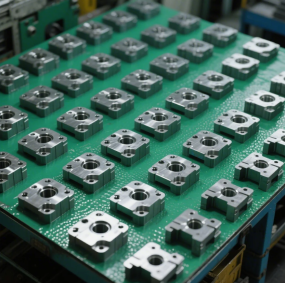

Repeatable precision for high-volume production

Superior surface finishes for implantable devices

Strict compliance with ISO 13485 and FDA regulations

Key Applications of CNC Machined Medical Parts

Our expertise covers various medical applications including:

Surgical instruments and handheld tools

Orthopedic implants and prosthetics

Diagnostic equipment components

Dental devices and implants

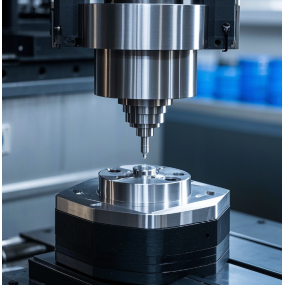

EMAR's Advanced CNC Medical Parts Machining Capabilities

With state-of-the-art 5-axis CNC machines and cleanroom facilities, we deliver:

Micro-machining for miniature components

Multi-material machining solutions

Full traceability and material certification

Post-processing including passivation and sterilization

As a trusted CNC machining partner for medical device manufacturers, EMAR combines technical expertise with rigorous quality control to produce components that meet the highest industry standards.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque