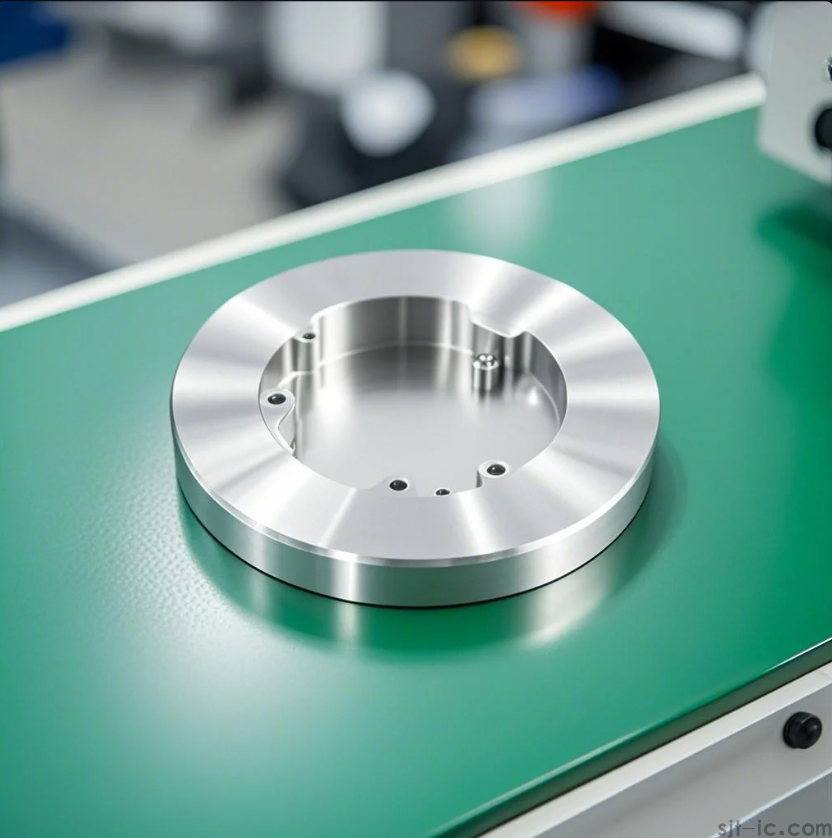

When it comes to manufacturing, CNC Machining simple parts is a fundamental process that many industries rely on. At EMAR, we specialize in delivering high-quality CNC machining services for a wide range of components, from the simplest to the most complex. This article will explore the process, benefits, and applications of CNC machining for simple parts, helping you understand why it's a preferred method for many manufacturers.

What Are Simple Parts in CNC Machining?

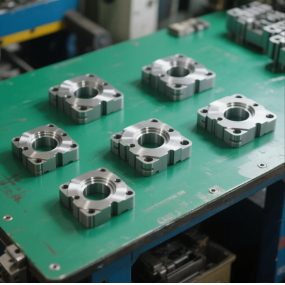

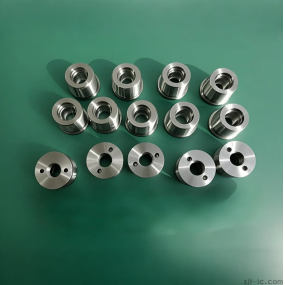

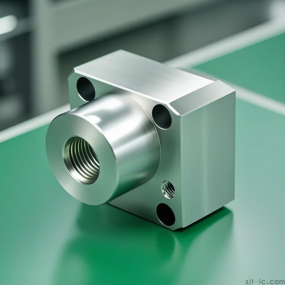

Simple parts in CNC machining refer to components with straightforward geometries, minimal features, and relatively easy-to-machine materials. These parts typically require fewer tool changes and simpler programming compared to complex components. Examples include brackets, spacers, washers, and basic shafts.

The Process of CNC Machining Simple Parts

The manufacturing process for simple parts follows these key steps:

Design Analysis: Our engineers review the part drawings or CAD files

Material Selection: Choosing the appropriate raw material (aluminum, steel, plastic, etc.)

Machine Setup: Configuring the CNC machine with proper tools and fixtures

Programming: Creating efficient toolpaths for the simple geometry

Machining: Executing the programmed operations

Quality Inspection: Verifying dimensions and surface finish

Advantages of Choosing EMAR for Your Simple Parts

At EMAR, we offer distinct advantages for CNC machining simple parts:

Cost-effective solutions due to reduced machining time

Fast turnaround times for simple geometries

High precision (±.005" standard tolerance)

Wide material selection from our extensive inventory

Scalable production from prototypes to large batches

Applications Across Industries

Our CNC machining services for simple parts serve various industries including:

Automotive: Bushings, spacers, and mounting brackets

Electronics: Heat sinks and enclosures

Industrial Equipment: Shafts and couplings

Medical: Instrument components

Whether you need a single prototype or mass production of simple parts, EMAR's CNC machining capabilities ensure quality, precision, and reliability. Contact us today to discuss your project requirements and experience our professional machining services.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque