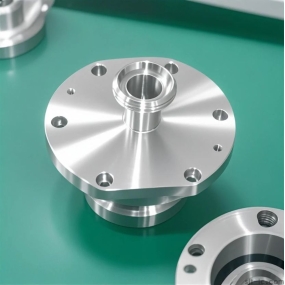

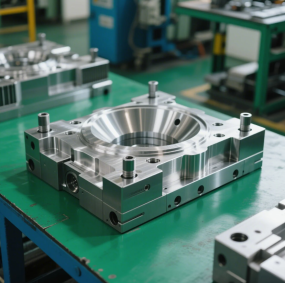

In the realm of precision manufacturing, CNC turbine parts machining stands as a critical process for industries demanding uncompromising accuracy and durability. As a leading CNC Machining service provider, EMAR specializes in delivering aerospace-grade turbine components that meet stringent quality standards.

Why CNC Machining for Turbine Components?

Turbine systems in aerospace, power generation, and industrial applications require components with micron-level tolerances. Our 5-axis CNC machining capabilities enable complex geometries in heat-resistant superalloys like Inconel and titanium, ensuring optimal aerodynamic performance and thermal stability.

EMAR's Technical Advantages in Turbine Part Production

1. High-speed machining centers with .001mm repeatability

2. Advanced cooling channel machining technology

3. CMM inspection and surface finish analysis

4. ISO 9001-certified quality management system

End-to-End Manufacturing Process

From 3D model validation to final deburring, our engineers implement DFM principles to optimize:

- Blade profile machining

- Disc/shaft interface surfaces

- Cooling hole drilling

- Vibration damper features

Discover how EMAR's CNC turbine parts machining solutions can enhance your equipment's efficiency and service life. Visit our website at https://www.sjt-ic.com/ for technical consultation and project evaluation.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque