What is CNC Aluminum Alloy Machining?

CNC aluminum alloy machining refers to the process of using computer numerical control (CNC) machines to precisely cut, shape, and finish aluminum alloy materials. This advanced manufacturing technique combines the lightweight properties of aluminum with the precision capabilities of CNC technology, making it ideal for producing high-quality components across various industries.

Benefits of CNC Machining for Aluminum Alloys

Aluminum alloys are among the most commonly machined materials due to their excellent properties:

- Lightweight yet durable - perfect for aerospace and automotive applications

- Excellent machinability with high dimensional stability

- Superior thermal and electrical conductivity

- Natural corrosion resistance

- Cost-effective material with good strength-to-weight ratio

Our CNC Aluminum Machining Capabilities

At EMAR, we specialize in CNC aluminum alloy machining services with state-of-the-art equipment and skilled technicians. Our capabilities include:

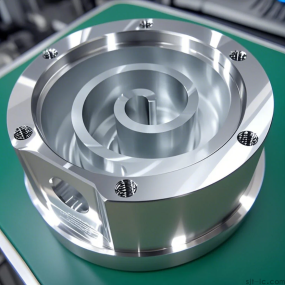

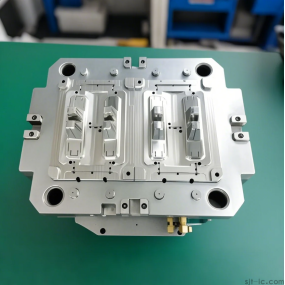

- 3-axis, 4-axis, and 5-axis CNC milling

- CNC turning for cylindrical aluminum parts

- High-speed machining for complex geometries

- Tolerance capabilities down to ±.005mm

- Surface finishes from rough machining to mirror polishing

Common Aluminum Alloys We Machine

We work with various aluminum alloy grades, each offering unique characteristics:

- 6061-T6 - Most common general-purpose alloy

- 7075-T6 - High strength for aerospace applications

- 2024 - Excellent fatigue resistance

- 5052 - Superior corrosion resistance

- 6063 - Excellent extrudability

Applications of CNC Machined Aluminum Parts

Our CNC aluminum machining services support numerous industries:

- Aerospace - Structural components, brackets, and housings

- Automotive - Engine parts, transmission components

- Electronics - Heat sinks, enclosures, connectors

- Medical - Surgical instruments, device components

- Industrial - Machinery parts, robotic components

Why Choose EMAR for Your Aluminum CNC Machining Needs?

As a professional CNC machining service provider, EMAR offers:

- Extensive experience with aluminum alloys and other materials

- Advanced CNC machines with tight tolerance capabilities

- Skilled engineers who understand aluminum's unique properties

- Quality assurance with comprehensive inspection equipment

- Competitive pricing and fast turnaround times

- One-stop solution from prototyping to mass production

Get Started with Your CNC Aluminum Project

Whether you need prototype quantities or high-volume production, our team is ready to assist with your aluminum machining requirements. Contact us today to discuss your project specifications and receive a competitive quote.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque