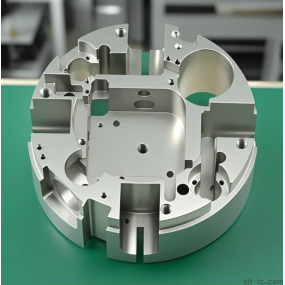

As a leading CNC Machining service provider, EMAR specializes in precision manufacturing of brass components for various industries. Our advanced CNC technology ensures exceptional accuracy and surface finish for all your brass product requirements.

Why Choose CNC Machining for Brass Products?

Brass is a popular material in manufacturing due to its excellent machinability, corrosion resistance, and electrical conductivity. CNC machining brass products offers several advantages:

High dimensional accuracy (±.005mm tolerance)

Superior surface finish options

Complex geometries achievable

Cost-effective for both prototypes and mass production

Our Brass CNC Machining Capabilities

EMAR's state-of-the-art CNC machines can handle various brass alloys including C36000 (free-cutting brass), C26000 (cartridge brass), and C28000 (Muntz metal). Our services include:

Precision turning and milling

Threading and tapping

Drilling and boring

Custom finishing (polishing, plating, anodizing)

Quality Assurance in Brass Component Manufacturing

We implement strict quality control measures for all CNC machined brass products:

Material certification verification

First-article inspection (FAI)

In-process dimensional checks

Final inspection with CMM when required

With our expertise in CNC machining brass components, EMAR delivers high-quality parts that meet your exact specifications. Contact us today to discuss your brass machining project requirements.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque