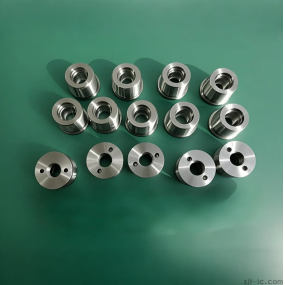

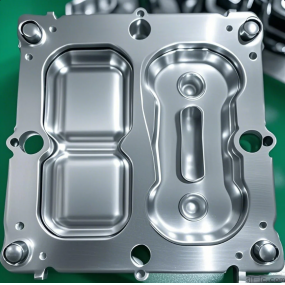

As a leading CNC Machining service provider, AOOM Technologies specializes in high-volume production of precision aluminum alloy components for industries ranging from aerospace to automotive. This article explores the technical advantages and process optimization strategies for CNC batch processing of aluminum alloys.

Why Choose CNC for Aluminum Alloy Batch Production?

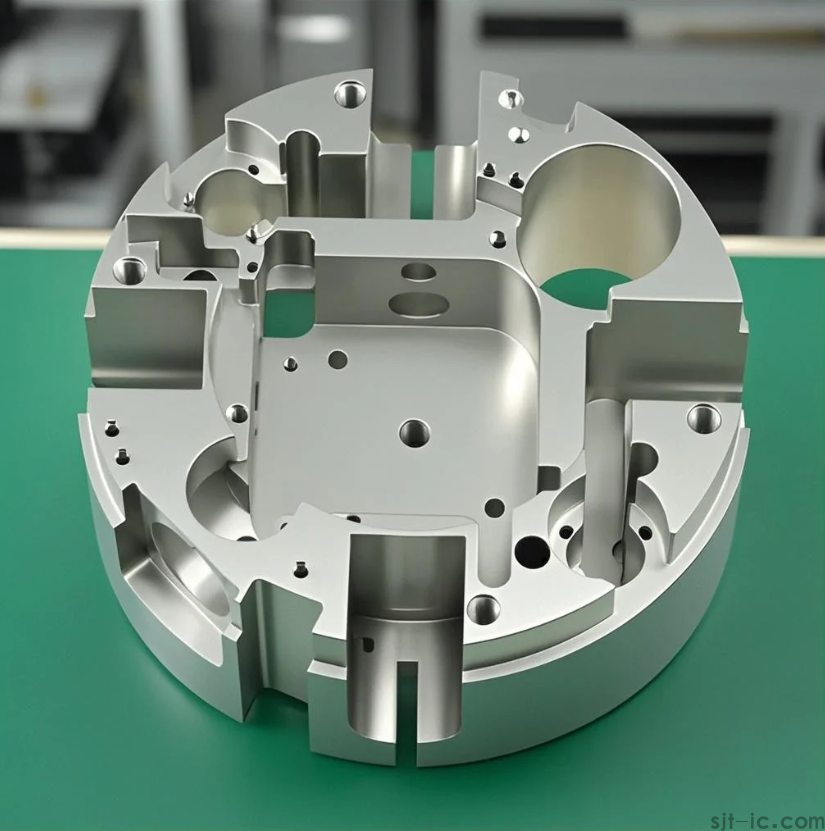

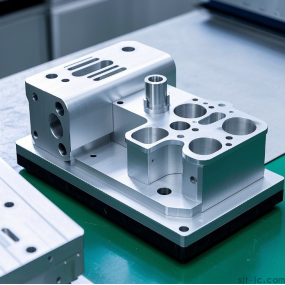

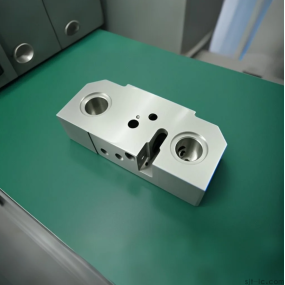

Aluminum alloys (particularly 6061, 7075, and 2024 grades) are ideal for CNC batch processing due to their excellent machinability-to-strength ratio. Our 5-axis CNC centers achieve ±.005mm tolerances while maintaining cycle times under 3 minutes for complex parts. The automated tool changers and pallet systems at AOOM enable uninterrupted 24/7 production.

Process Optimization for Mass Production

1. Fixture Design: Custom modular fixtures allow simultaneous machining of 8-12 workpieces

2. Toolpath Strategy: High-efficiency trochoidal milling reduces tool wear by 40%

3. Coolant Management

Quality Assurance Protocols

Every batch undergoes:

First-article inspection with CMM (Coordinate Measuring Machine)

Statistical process control (SPC) monitoring

Surface roughness verification (Ra .8μm achievable)

Industry Applications

Our CNC-machined aluminum components serve critical functions in:

• Drone frames (weight-optimized structures)

• Automotive powertrains (heat-treated 7075-T6 parts)

• Medical devices (anodized surgical components)

At AOOM Technologies, we combine German-made DMG MORI equipment with ISO 9001-certified processes to deliver 50,000+ aluminum parts monthly. Contact our engineering team at www.aoomtech.com for DFM analysis and batch production quotes.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque