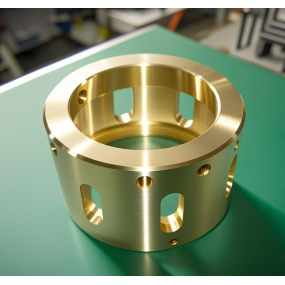

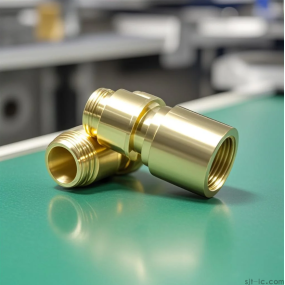

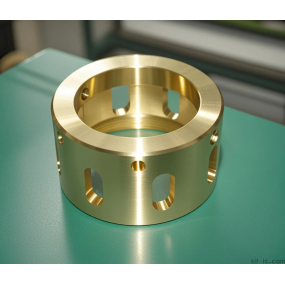

As a leading CNC Machining service provider, EMAR specializes in manufacturing high-precision vacuum pump components for various industrial applications. Our advanced CNC technology ensures exceptional accuracy and repeatability for these critical parts.

Why Choose CNC Machining for Vacuum Pump Components?

Vacuum pump components require extreme precision to maintain tight tolerances and perfect sealing surfaces. Our CNC machining processes deliver:

±.005mm dimensional accuracy

Superior surface finishes (Ra .4μm achievable)

Complex geometries in single setups

Material versatility (aluminum, stainless steel, brass, etc.)

Our Vacuum Pump Component Manufacturing Capabilities

EMAR's 5-axis CNC machines produce various vacuum pump parts including:

Rotors and stators

Housings and end plates

Valve plates and seals

Connecting rods and shafts

Quality Assurance Process

Every component undergoes rigorous inspection using CMM, surface roughness testers, and helium leak detectors to ensure they meet vacuum-grade specifications. Our ISO 9001-certified quality system guarantees consistent performance.

Advantages of Partnering with EMAR

With 15+ years in precision machining, we offer:

DFM (Design for Manufacturing) support

Prototype to mass production services

Short lead times (as fast as 5 days)

Competitive pricing for OEMs

Contact our engineering team today at www.sjt-ic.com to discuss your vacuum pump component requirements.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque