As a leading CNC Machining service provider, EMAR specializes in manufacturing high-precision aluminum components for industries ranging from aerospace to electronics. This article explores the technical process, quality control measures, and why precision matters in aluminum part fabrication.

Why Choose CNC for Precision Aluminum Parts?

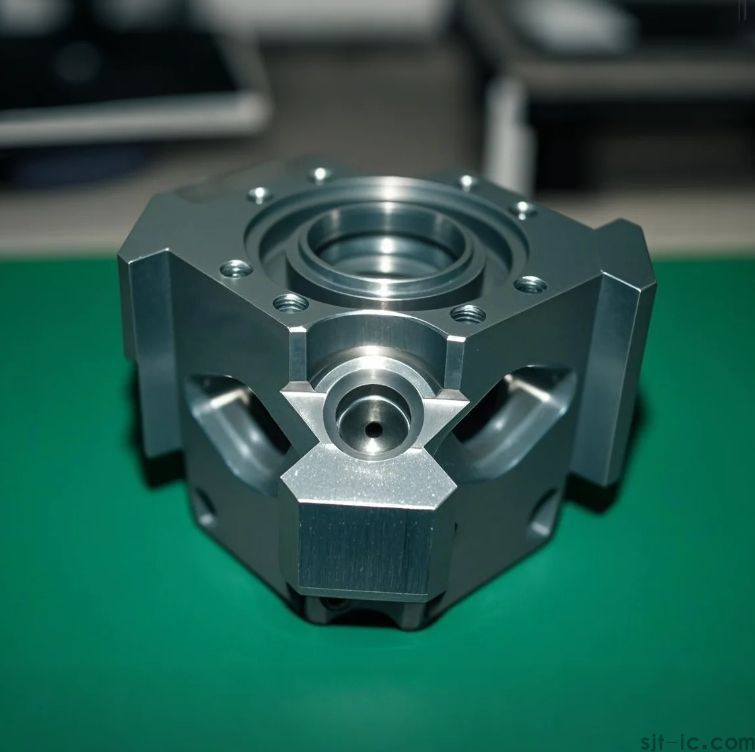

Aluminum's excellent machinability and strength-to-weight ratio make it ideal for precision components. CNC technology achieves tolerances as tight as ±.005mm, with surface finishes down to Ra .4μm. Our 5-axis machines at EMAR can create complex geometries impossible with conventional machining.

The Precision Machining Process

1. Material Selection: We use 6061, 7075, and other aerospace-grade aluminum alloys

2. CAD/CAM Programming: Our engineers optimize tool paths for precision and efficiency

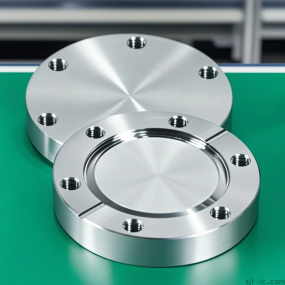

3. Machining: Multi-axis CNC centers perform milling, drilling, and tapping operations

4. Quality Inspection: CMM and optical comparators verify dimensional accuracy

EMAR's Competitive Advantages

With 15+ years in CNC machining, we offer:

• 50+ CNC machines including Swiss-type lathes

• ISO 9001-certified quality system

• Fast turnaround (as quick as 72 hours)

• Full-service capabilities from prototyping to mass production

Applications of Precision Aluminum Parts

Our components serve critical functions in:

• Automotive: Engine brackets, transmission parts

• Medical: Surgical instrument components

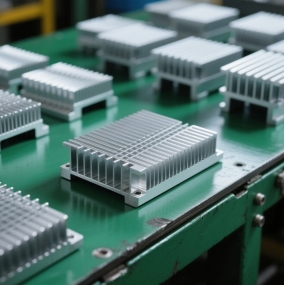

• Electronics: Heat sinks, enclosures

• Robotics: Lightweight structural elements

Visit EMAR's official website to request a free project evaluation and see how our precision machining solutions can meet your specific requirements.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque