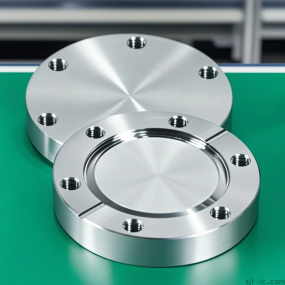

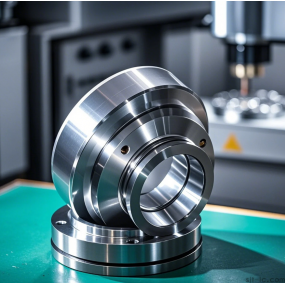

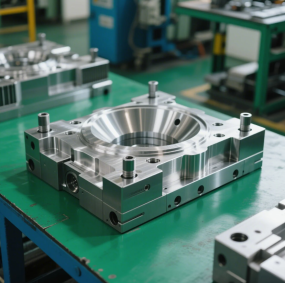

As a leading CNC Machining metal service provider, EMAR specializes in delivering high-precision components for industries ranging from aerospace to automotive. Our advanced CNC technology ensures exceptional accuracy and repeatability for your most demanding metal parts.

Why Choose CNC Machining for Metal Components?

CNC machining offers unparalleled advantages for metal part manufacturing. The process enables:

Tolerances within ±.005mm for critical dimensions

Superior surface finishes down to Ra .4μm

Efficient production of complex geometries

Consistent quality across small to medium batch sizes

Our CNC Metal Machining Capabilities

EMAR's facility features state-of-the-art 5-axis CNC machines capable of processing various metals:

Aluminum alloys (6061, 7075, etc.)

Stainless steel (303, 304, 316)

Titanium (Grade 2, Grade 5)

Brass and copper alloys

Tool steels

Quality Assurance Process

Every CNC machined metal part undergoes rigorous inspection:

First-article inspection with CMM verification

In-process dimensional checks

Final quality control including surface roughness testing

Material certification review

Industries We Serve

Our CNC metal machining solutions support:

Aerospace components

Medical device parts

Automotive prototypes

Industrial equipment

Electronics enclosures

With EMAR's CNC machining expertise, you receive more than parts - you gain a manufacturing partner committed to your success. Contact our engineering team today to discuss your metal machining requirements.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque