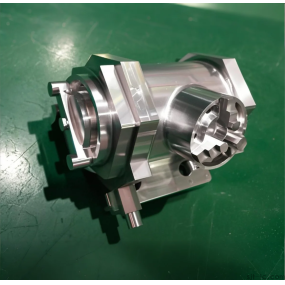

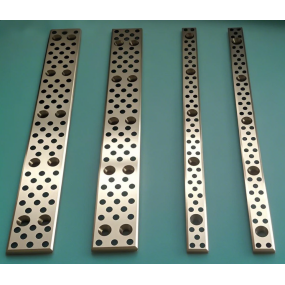

As a leading CNC Machining service provider, EMAR specializes in manufacturing high-precision tungsten steel components for demanding industrial applications. Our advanced machining capabilities ensure exceptional quality and durability for these challenging materials.

Why Choose Tungsten Steel for CNC Machining?

Tungsten steel (also called cemented carbide) offers superior hardness, wear resistance, and thermal stability compared to conventional metals. These properties make it ideal for cutting tools, molds, and high-stress mechanical components. However, its extreme hardness requires specialized CNC machining techniques that EMAR has mastered through years of experience.

Our CNC Machining Process for Tungsten Steel

EMAR's precision manufacturing process includes:

Material selection: Using premium-grade tungsten carbide blanks

Advanced tooling: Diamond-coated cutters and specialized grinding tools

Precision machining: 5-axis CNC mills with rigid setups

Quality control: CMM inspection and surface roughness testing

Applications of Our Machined Tungsten Steel Parts

Our CNC Machining Tungsten Steel Parts serve critical functions in:

Metal cutting and forming tools

Oil and gas drilling components

Aerospace and defense applications

Medical device manufacturing

EMAR's Competitive Advantages

With ISO 9001 certification and over 15 years in precision machining, we offer:

±.005mm machining tolerance

Custom solutions for complex geometries

Fast turnaround with reliable delivery

Technical support from our engineering team

Contact EMAR today at www.sjt-ic.com to discuss your tungsten steel machining requirements. Our experts will provide optimized solutions for your most challenging applications.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque