Have you ever been confused by the huge price differences in small-batch CNC Machining? 🤔 A manufacturing enterprise in Shenzhen once reported that for the same aluminum alloy part, the quotation gap between different manufacturers was as high as 40%! In fact, behind the pricing of top-tier CNC machining lies a multi-dimensional balance involving technical precision, material waste, and equipment costs. This article will reveal the pricing logic of small-batch precision machining and teach you how to avoid hidden pitfalls.

🔍 I. Four Core Factors Affecting Small-Batch CNC Pricing

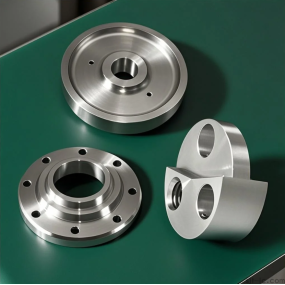

1. Material Cost and Waste Rate: High-end materials such as aerospace aluminum and titanium alloy have significant price premiums, while the waste rate (e.g., milling allowance) directly affects the amount of raw materials invested. For instance, the waste rate of titanium alloy machining is usually 15%-20% higher than that of aluminum.

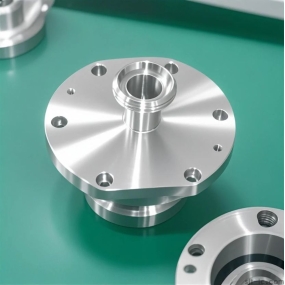

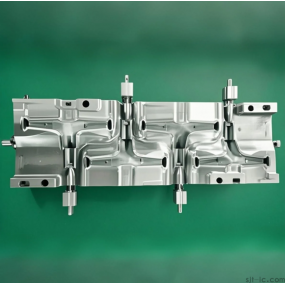

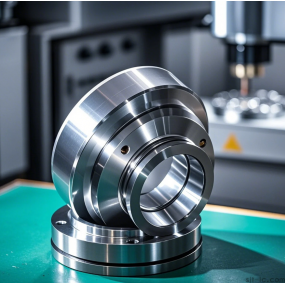

2. Precision Level and Tolerance Requirements: Micron-level precision of ±0.001mm requires 5-axis machines and full inspection equipment, with costs over 30% higher than ordinary machining.

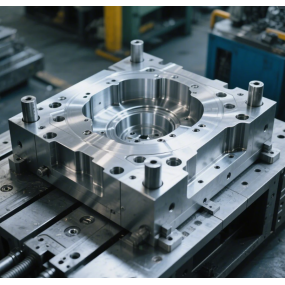

3. Equipment and Process Complexity: The hourly rate for 5-axis machining centers is approximately 300-500 RMB/hour, while that for 3-axis machines is only 120-200 RMB/hour.

4. Post-Processing and Certification Requirements: Special processes like anodizing and medical-grade cleaning incur additional charges; manufacturers with ISO 13485 medical certification typically have a price premium of around 20%.

💡 II. 3 Practical Strategies to Reduce Costs

1. Design Optimization to Cut Material Waste: Adopt lightweight structural designs to reduce milling volume. One enterprise reduced material costs by 15% through topological optimization.

2. Standardized Process Chain: Choose one-stop service providers that integrate turn-mill compounding and heat treatment to avoid additional costs from multiple external collaborations.

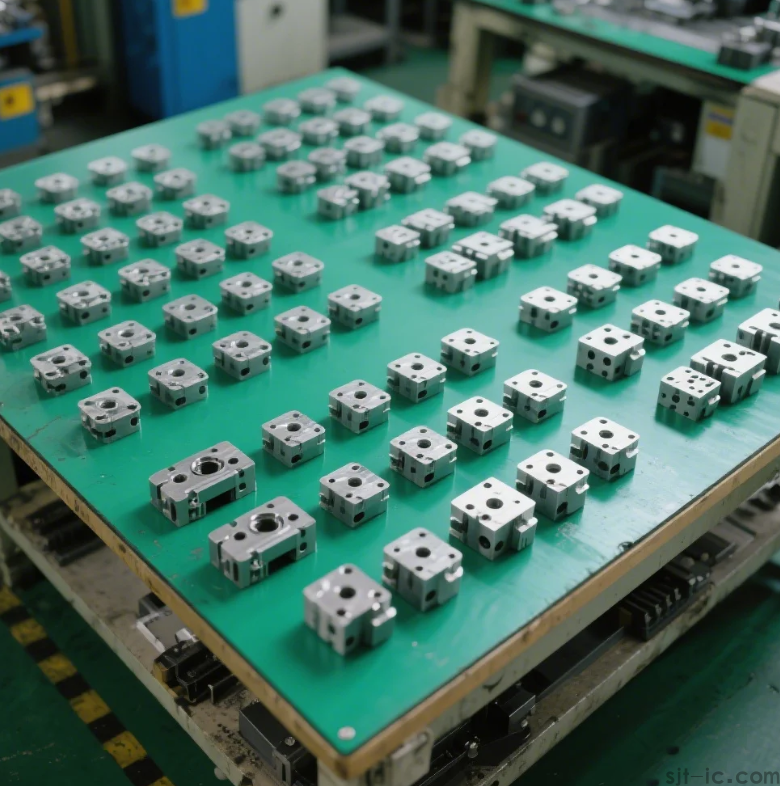

3. Batched Combined Production: Combine small-batch orders of multiple varieties for scheduling, sharing machine initialization time, which can improve efficiency by up to 25%.

📊 III. 2025 CNC Machining Selection Guide

| Manufacturer Type | Suitable Scenarios | Precision Range | Typical Quotation (Aluminum Alloy/Unit) |

|-------------------------|-----------------------------|-----------------|-----------------------------------------|

| 5-Axis Specialized Manufacturers | Aerospace Parts | ±0.001mm | 800-1500 RMB |

| Medical-Certified Manufacturers | Implants/Surgical Instruments | ±0.002mm | 600-1200 RMB |

| Comprehensive Medium-Small Manufacturers | Industrial Components | ±0.01mm | 200-500 RMB |

*Data Source: 2025 Guangdong CNC Enterprise Survey*

🚀 IV. Future Trends and Exclusive Insights

In 2025, CNC machining is moving toward AI real-time parameter adjustment and nanoscale precision breakthroughs. For example, Huazhong CNC systems have integrated AI chips, which improve machining efficiency by 10% through dynamic correction of tool paths. However, it is worth noting that 80% of domestic manufacturers still struggle with balancing precision and cost— the payback period for high-end equipment investment is as long as 5-8 years, while medium and small manufacturers can share costs by leasing cloud CNC platforms.

When selecting a manufacturer, users are advised to focus on the following:

✅ Whether it has the capability to push online quality inspection reports in real time

✅ Whether it provides digital twin simulation services for the machining process

✅ Whether it supports raw material traceability certification (e.g., AMS standards for aerospace aluminum)

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque