As a leading CNC Machining service provider, EMAR specializes in manufacturing high-precision automotive molds for global manufacturers. Our advanced 5-axis CNC systems and ISO-certified processes ensure mold solutions that meet strict automotive industry standards.

Why Choose CNC for Automotive Mold Manufacturing?

CNC machining offers unparalleled advantages for automotive mold production. The technology enables micron-level accuracy (±.01mm tolerance) for complex mold geometries, including:

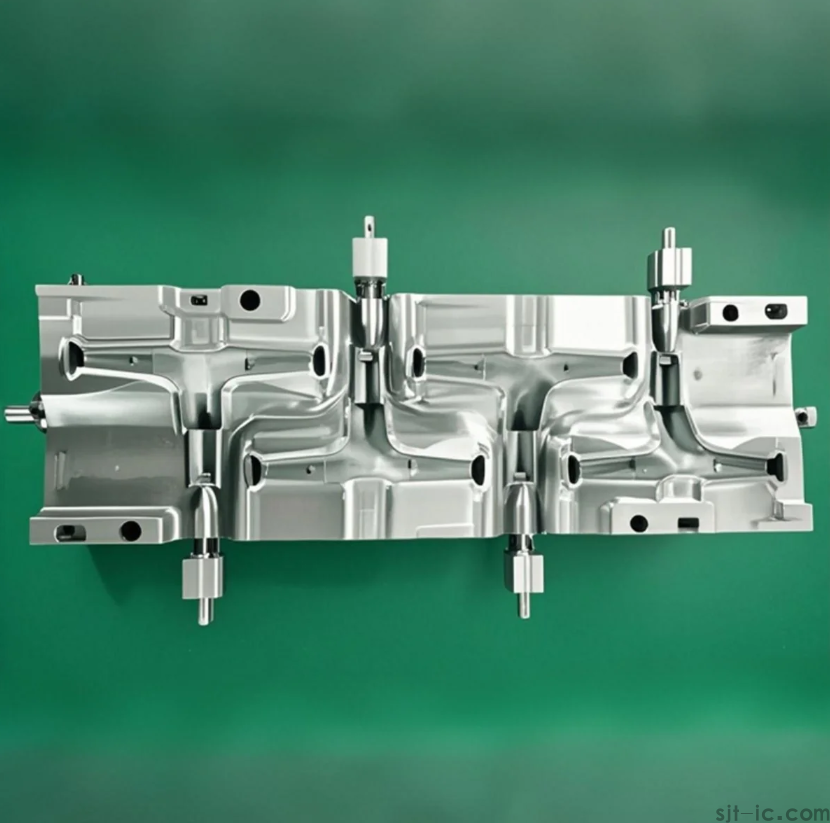

Injection molds for interior components

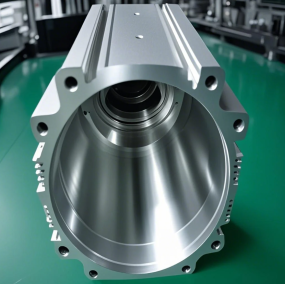

Die-casting molds for engine parts

Stamping molds for body panels

Our Automotive Mold CNC Workflow

EMAR's 7-step quality-controlled process:

3D CAD model analysis

Toolpath optimization for mold cavities

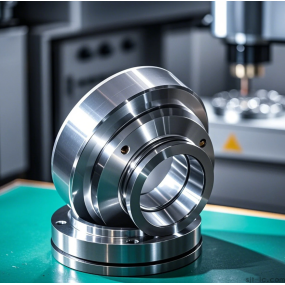

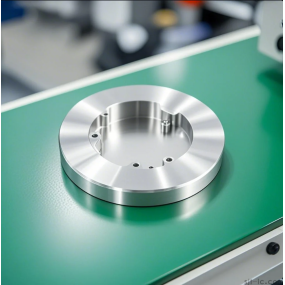

Precision machining with hardened tool steel

EDM finishing for intricate details

Surface treatment (nitriding/PVD coating)

CMM inspection

Production trial run

Key Benefits for Automotive Clients

Our CNC machining services deliver:

30-50% faster lead times compared to conventional methods

Extended mold lifespan through premium material selection

Consistent quality for high-volume production

DFM support to optimize mold designs

With over 15 years of experience in CNC machining automotive molds, EMAR has served Tier 1 suppliers and OEMs worldwide. Our technical team can handle projects from prototype to mass production with strict confidentiality agreements.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque