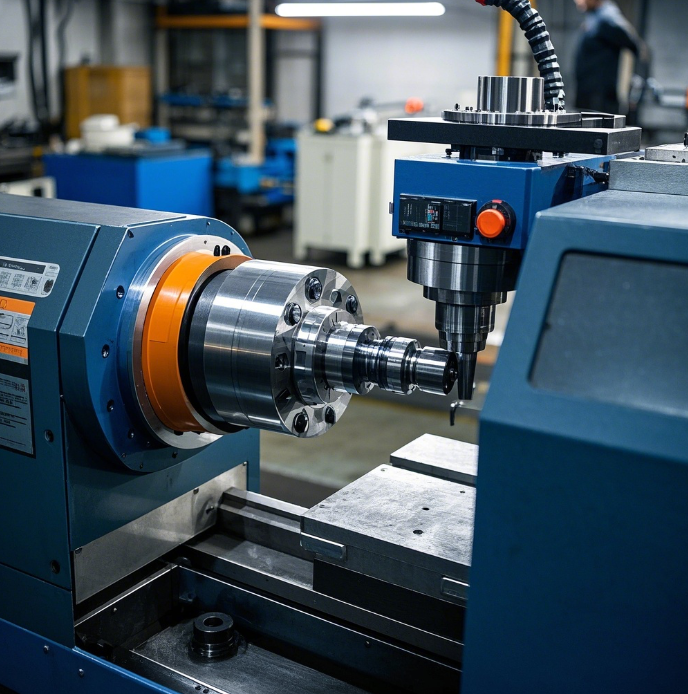

Why EMAR Stands Out in Precision CNC Machining

As a leading CNC turning manufacturer, EMAR combines advanced technology with rigorous quality control to deliver components with micron-level accuracy. Our ISO-certified facility houses state-of-the-art 5-axis CNC lathes capable of processing aerospace-grade materials like titanium and Inconel.

End-to-End Solutions for Complex Projects

From prototype development to mass production, we offer integrated services including CAD/CAM programming, toolpath optimization, and post-processing. Our engineers specialize in reducing cycle times by 30% through intelligent fixture design and cutting parameter optimization.

Industry-Specific Expertise

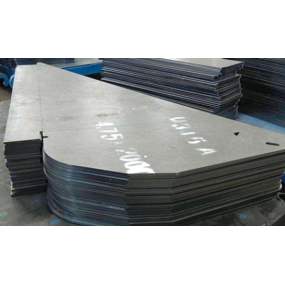

With 15+ years serving medical, automotive, and semiconductor sectors, EMAR understands critical tolerances (±.005mm) and surface finish requirements (Ra .2μm). All parts undergo CMM inspection and material certification.

Global Supply Chain Reliability

Our Shanghai-based factory features automated production monitoring with real-time quality alerts, ensuring on-time delivery for international clients. Just-in-time inventory management minimizes lead times to 7-10 days for standard orders.

Competitive Pricing Without Compromise

Through lean manufacturing principles and bulk material procurement, EMAR provides cost savings of 15-20% compared to European counterparts while maintaining ITAR-compliant data security protocols.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque