In the realm of precision manufacturing, CNC stainless steel machining parts customization stands as a cornerstone for industries demanding durability, corrosion resistance, and tight tolerances. At EMAR, we specialize in delivering high-quality CNC-machined stainless steel components tailored to your exact specifications, ensuring optimal performance for aerospace, medical, automotive, and industrial applications.

Why Choose CNC Machining for Stainless Steel Parts?

Stainless steel's inherent properties—such as high strength and chemical resistance—make it ideal for critical applications. However, machining this material requires advanced expertise. Our CNC machining processes leverage state-of-the-art equipment (e.g., 5-axis mills) and tooling strategies to overcome challenges like work hardening, achieving:

- Precision tolerances up to ±.005mm

- Superior surface finishes (Ra .4μm achievable)

- Complex geometries with repeatability

EMAR's Customization Capabilities

We transform your designs into functional parts through a streamlined workflow:

- Material Selection: 304/316L, 17-4PH, or other grades per your requirements.

- CAD/CAM Optimization: DFM analysis to reduce costs and lead times.

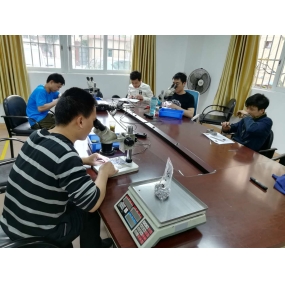

- Multi-Axis Machining: Efficient production of prototypes to high-volume batches.

- Quality Assurance: CMM inspection and ISO 9001-certified processes.

Industries We Serve

Our custom stainless steel parts are trusted by:

- Medical: Surgical instruments, implantable components.

- Automotive: Fuel system parts, sensors.

- Energy: Valves, pump components for corrosive environments.

Partner with EMAR for CNC machining that balances precision, speed, and cost-efficiency. Contact our team to discuss your project requirements today.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque