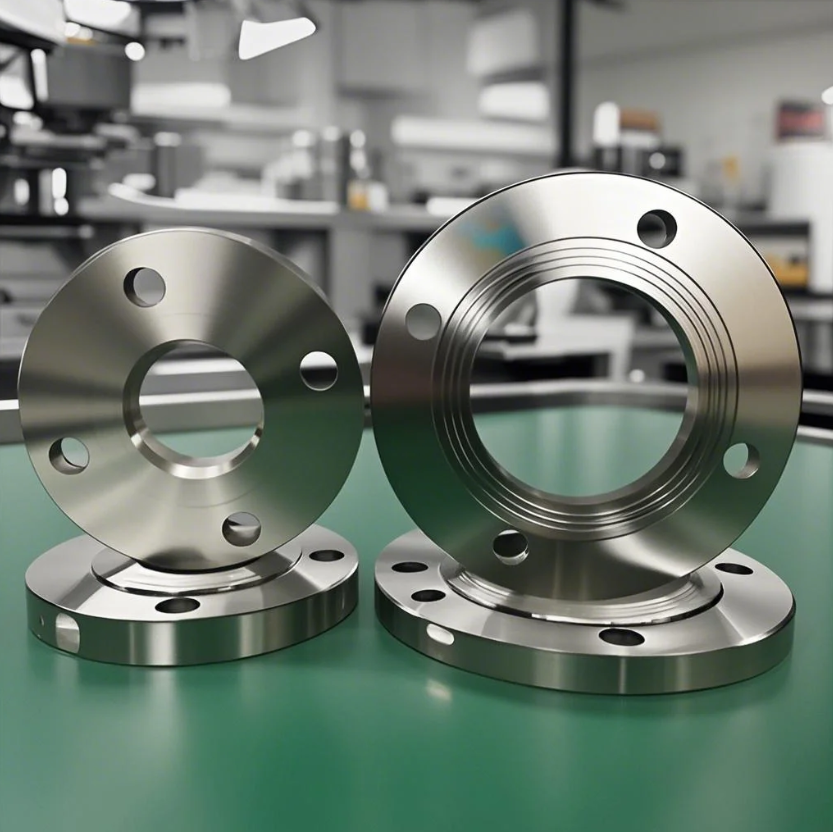

In precision manufacturing, CNC stainless steel flange machining stands as a critical process for industries requiring durable, corrosion-resistant components. EMAR Company specializes in delivering high-tolerance flanges that meet stringent international standards, serving sectors from oil & gas to aerospace.

Why Choose CNC Machining for Stainless Steel Flanges?

Our CNC machining technology ensures dimensional accuracy within ±.01mm for flanges, addressing common pain points like seal failure and pressure leakage. The automated process eliminates human error while maintaining surface finishes down to Ra .8μm - crucial for flange mating surfaces.

EMAR's Technical Capabilities

With 15+ years of expertise, we handle:

- Materials: 304/316L, duplex stainless steels

- Dimensions: OD 10mm-200mm, thickness up to 300mm

- Processes: Turning, milling, drilling, threading

- Certifications: ISO 9001, AS910, PED compliant

Quality Assurance Protocol

Every flange undergoes rigorous inspection including:

- CMM verification (Zeiss Contura G2)

- Pressure testing to API 6A standards

- Material composition analysis via spectrometer

For stainless steel flange machining that combines precision with industrial durability, EMAR Company provides turnkey solutions from prototyping to mass production. Our 24/7 engineering support ensures your project specifications are met with zero compromise.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque