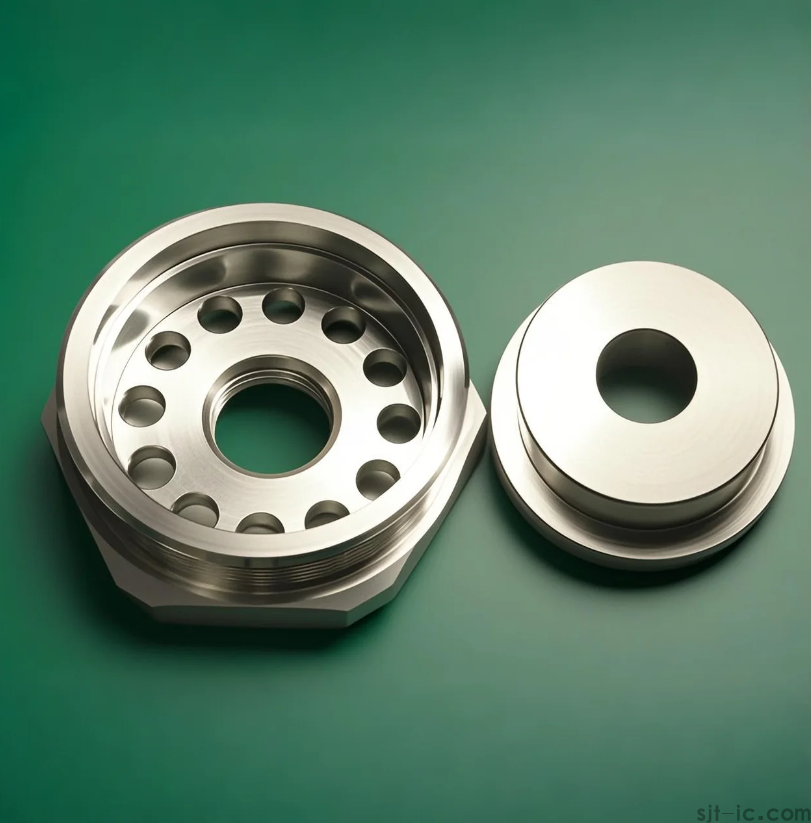

As a professional CNC steel custom machining service provider, EMAR Company specializes in delivering precision-engineered metal components for industrial applications. This article will explore the technical process, advantages, and industry-specific solutions of steel CNC Machining.

Understanding CNC Steel Custom Machining

CNC steel custom machining refers to the computer-controlled subtractive manufacturing process that shapes raw steel materials into precise components. Unlike standard machining, custom machining involves tailored solutions for unique dimensional requirements, surface finishes, and mechanical properties.

Key Advantages of Our Steel CNC Machining Services

1. Material Versatility: We machine various steel grades including carbon steel, alloy steel, and tool steel

2. ±.005mm Tolerance: High-precision capabilities for critical applications

3. Complex Geometry: 5-axis machining for intricate designs

4. Surface Treatment: Optional polishing, coating, or heat treatment

Our CNC Steel Custom Machining Workflow

1. Design Analysis: Our engineers review your CAD files for manufacturability

2. Material Selection: Recommending optimal steel grade based on application requirements

3. Precision Machining: Using advanced CNC mills and lathes

4. Quality Inspection: CMM measurement and surface testing

5. Post-Processing: Applying specified surface treatments

6. Packaging & Delivery: Secure packaging for international shipping

Industry Applications

Our custom steel machining serves:

Automotive: Engine components, transmission parts

Aerospace: Structural elements, landing gear parts

Industrial Machinery: Shafts, gears, hydraulic components

Medical: Surgical instrument components

Why Choose EMAR for Your Steel CNC Needs?

With 15+ years of CNC machining experience, EMAR Company offers:

ISO 9001-certified production facility

50+ CNC machines with automatic tool changers

Dedicated engineering support team

Competitive pricing with fast turnaround (as quick as 72 hours)

Comprehensive quality control system

For your CNC steel custom machining projects, contact EMAR Company at www.sjt-ic.com to request a free quotation and DFM analysis today.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque