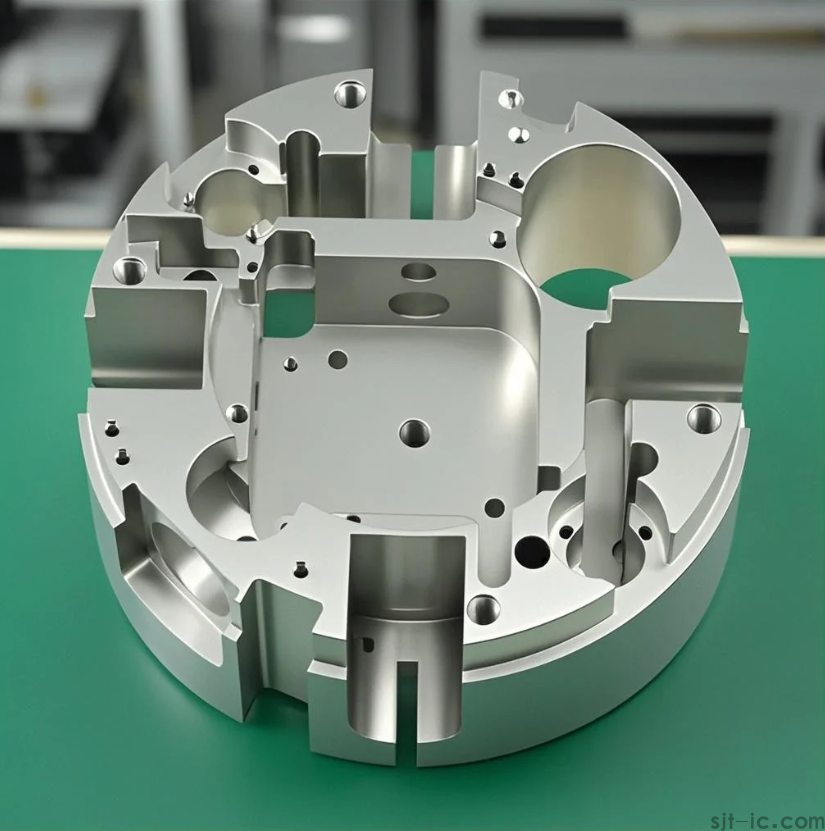

What Makes a Reliable CNC Precision Parts Manufacturing Factory?

When searching for a CNC precision parts manufacturing factory, professionals prioritize technical capabilities, quality control systems, and production efficiency. At EMAR, we've built our reputation on delivering high-precision machined components that meet the strictest industry standards across aerospace, medical, automotive, and electronics sectors.

Our Advanced Manufacturing Capabilities

Our factory is equipped with state-of-the-art CNC Machining centers including 5-axis milling machines, Swiss-type lathes, and multi-tasking machines. This advanced equipment allows us to produce complex geometries with tolerances as tight as ±.005mm. We specialize in:

- Micro-machining for miniature components

- High-volume production with consistent quality

- Prototyping and rapid turnaround services

- Exotic material machining (titanium, Inconel, PEEK, etc.)

Quality Assurance System

Quality is non-negotiable in precision parts manufacturing. Our ISO 9001:2015 certified facility implements rigorous quality control measures at every production stage:

- First-article inspection (FAI) with comprehensive reports

- In-process dimensional verification

- Surface finish analysis using advanced profilometers

- Material certification and traceability

- Final inspection with CMM (Coordinate Measuring Machine)

Industry-Specific Solutions

Understanding that different industries have unique requirements, we've developed specialized manufacturing protocols:

- Aerospace: AS910 compliant machining with full documentation

- Medical: Biocompatible materials with ultra-smooth finishes

- Automotive: High-strength components for performance applications

- Electronics: Precision enclosures and heat sinks

Why Choose EMAR as Your CNC Precision Parts Partner?

As a leading CNC precision parts manufacturing factory, EMAR offers distinct advantages:

- 15+ years of specialized machining experience

- DFM (Design for Manufacturing) support to optimize your designs

- Flexible production volumes from prototypes to mass production

- Competitive pricing without compromising quality

- On-time delivery with real-time production tracking

Our Material Expertise

We machine a wide range of materials to meet diverse application requirements:

- Metals: Aluminum, stainless steel, brass, titanium, magnesium

- Plastics: Delrin, PEEK, Ultem, PTFE, nylon

- Exotic alloys: Inconel, Monel, Hastelloy, Kovar

Surface Treatment Options

To enhance functionality and aesthetics, we offer various surface finishing services:

- Anodizing (Type II and Type III)

- Plating (nickel, chrome, zinc, gold)

- Passivation for corrosion resistance

- Bead blasting and polishing

- Painting and powder coating

Streamlined Order Process

We've simplified the procurement process for our clients:

- Submit your CAD drawings (STEP, IGES, SolidWorks formats preferred)

- Receive DFM analysis and quotation within 24 hours

- Approve samples (if required)

- Production begins with regular quality updates

- Parts delivered with complete inspection documentation

For organizations seeking a trustworthy CNC precision parts manufacturing factory, EMAR combines technical excellence with responsive service. Contact our engineering team today to discuss your project requirements and discover how we can add value to your supply chain.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque