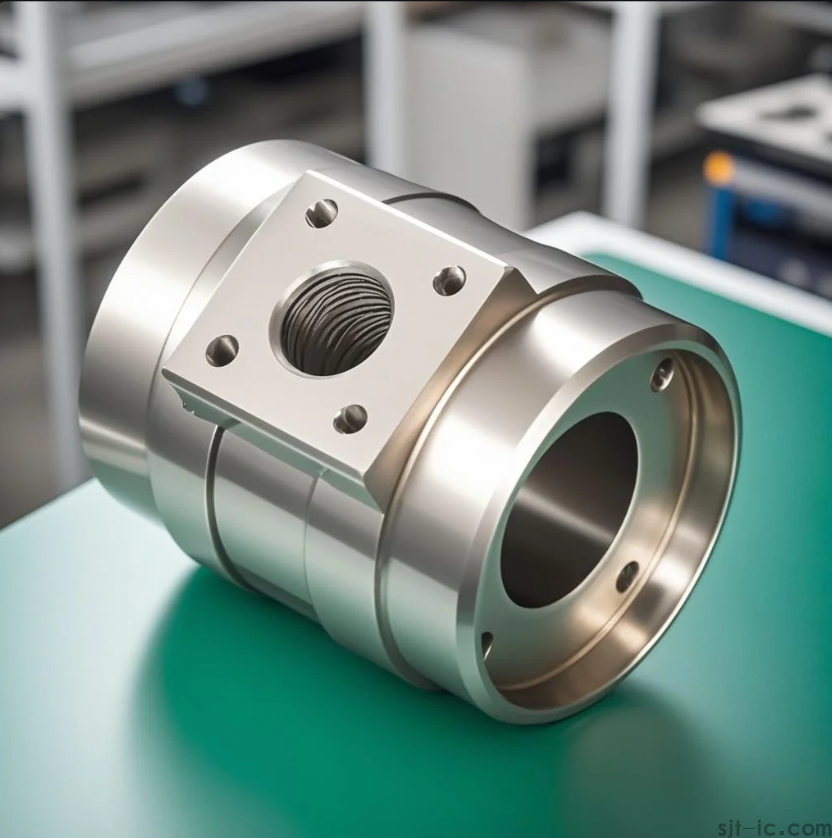

As a leading CNC Machining service provider, EMAR specializes in manufacturing precision mechanical components for various industries. Our advanced CNC technology ensures exceptional accuracy and repeatability for your custom parts.

Understanding CNC Machined Mechanical Parts

Custom mechanical parts fabrication through CNC processes involves subtractive manufacturing where computer-controlled machines remove material from solid blocks to create complex geometries. This method offers superior dimensional accuracy and surface finishes compared to conventional machining.

Our CNC Machining Capabilities

EMAR's facility houses state-of-the-art CNC milling and turning centers capable of producing parts with tolerances as tight as ±.005mm. We work with various materials including:

- Aluminum alloys (6061, 7075)

- Stainless steel (303, 304, 316)

- Brass and copper alloys

- Engineering plastics (PEEK, Delrin)

Customization Process at EMAR

Our custom parts manufacturing follows a streamlined workflow:

- Technical consultation and DFM analysis

- Material selection and procurement

- Precision CNC programming

- Quality-controlled machining

- Surface treatment (if required)

- Comprehensive inspection

Why Choose EMAR for Your CNC Needs

With over 15 years of experience in precision machining, we offer:

- ISO 9001:2015 certified processes

- Fast turnaround (prototypes in 3-5 days)

- Competitive pricing for small to large batches

- Comprehensive quality assurance

- Technical support throughout your project

Contact EMAR today at www.sjt-ic.com to discuss your CNC machining requirements. Our engineering team will provide expert solutions tailored to your specific application needs.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque