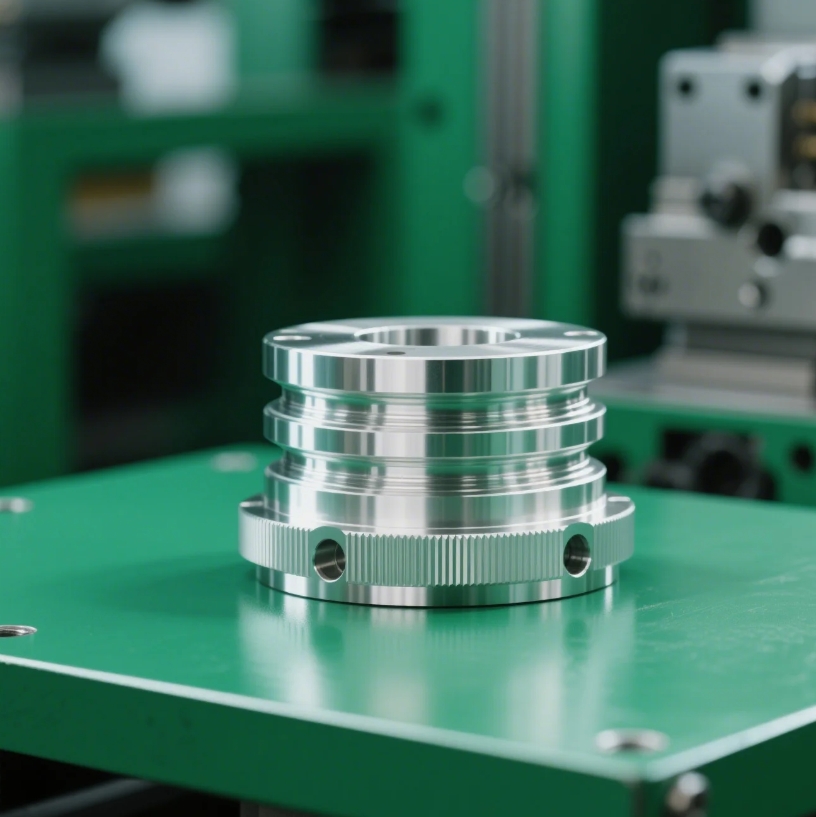

As a professional CNC Machining service provider, EMAR Technology is often asked by engineers and procurement managers: How precise can CNC machining be when working with aluminum? This article will provide a technical breakdown of achievable tolerances, influencing factors, and best practices for optimal results.

Standard Precision Levels in Aluminum CNC Machining

For most aluminum alloys (6061, 7075, etc.), standard CNC machining can typically achieve:

- ±.005" (±.127mm) for general machining

- ±.001" (±.025mm) for high-precision applications

- Surface finishes down to Ra .8μm with proper tooling

These tolerances meet the requirements of 90% industrial applications including aerospace brackets and electronic enclosures.

Key Factors Affecting Machining Accuracy

Several variables influence the final precision:

- Machine Capability: Our 5-axis CNC centers maintain positioning accuracy of ±.0002"

- Material Properties: Aluminum's thermal expansion requires climate-controlled workshops

- Tooling Selection: Carbide end mills with diamond coatings ensure consistent performance

- Post-processing: Secondary operations like anodizing may affect dimensional stability

EMAR's Precision Assurance System

We guarantee ultra-precise aluminum machining through:

- ISO 9001-certified quality control processes

- In-process inspection with CMM equipment (accuracy to .0001")

- Temperature-stabilized production environment (±1°C)

- DFM analysis to optimize designs for manufacturability

Our technical team can advise on balancing precision requirements with cost efficiency for your specific application.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque