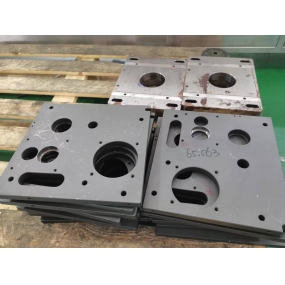

As a professional CNC precision metal parts processing provider, EMAR Company understands that cost is a critical factor for procurement managers and engineers when selecting machining services. This article breaks down the key elements influencing pricing and how we deliver value at www.sjt-ic.com.

Factors Affecting CNC Machining Costs

The price of CNC precision hardware parts depends on multiple variables:

- Material selection: Aluminum, stainless steel, and titanium have different base costs

- Part complexity: Intricate geometries require more machining time

- Surface finish requirements: Additional polishing/anodizing increases cost

- Order quantity: Higher volumes typically reduce unit price

Our Competitive Pricing Strategy

EMAR optimizes costs through:

- Advanced 5-axis CNC machines reducing setup time

- Bulk material procurement discounts

- Efficient nesting software minimizing material waste

- Transparent quoting with no hidden fees

Value-Added Services

Beyond competitive CNC machining costs, we provide:

- Free DFM (Design for Manufacturing) analysis

- ISO 9001 certified quality control

- Expedited prototyping services

- Global logistics support

For a customized quote, visit our website or contact our engineering team. EMAR delivers precision machining solutions balancing quality, speed, and cost-effectiveness for your project requirements.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque