In the world of CNC parts machining, precision is the cornerstone of quality. Whether you're a procurement manager, engineer, or business owner, understanding how to achieve and maintain high accuracy is critical for project success. At EMAR, we specialize in delivering precision CNC Machining solutions tailored to your exact specifications. Here’s a breakdown of the key factors that ensure dimensional accuracy and repeatability in CNC machining.

1. Advanced Machine Calibration and Maintenance

The foundation of precision lies in the CNC equipment itself. Regular calibration and maintenance of machines—such as checking spindle alignment, ball screw wear, and axis backlash—are non-negotiable. EMAR invests in state-of-the-art CNC machines with closed-loop feedback systems to minimize errors during CNC part production.

2. High-Quality Tooling and Material Selection

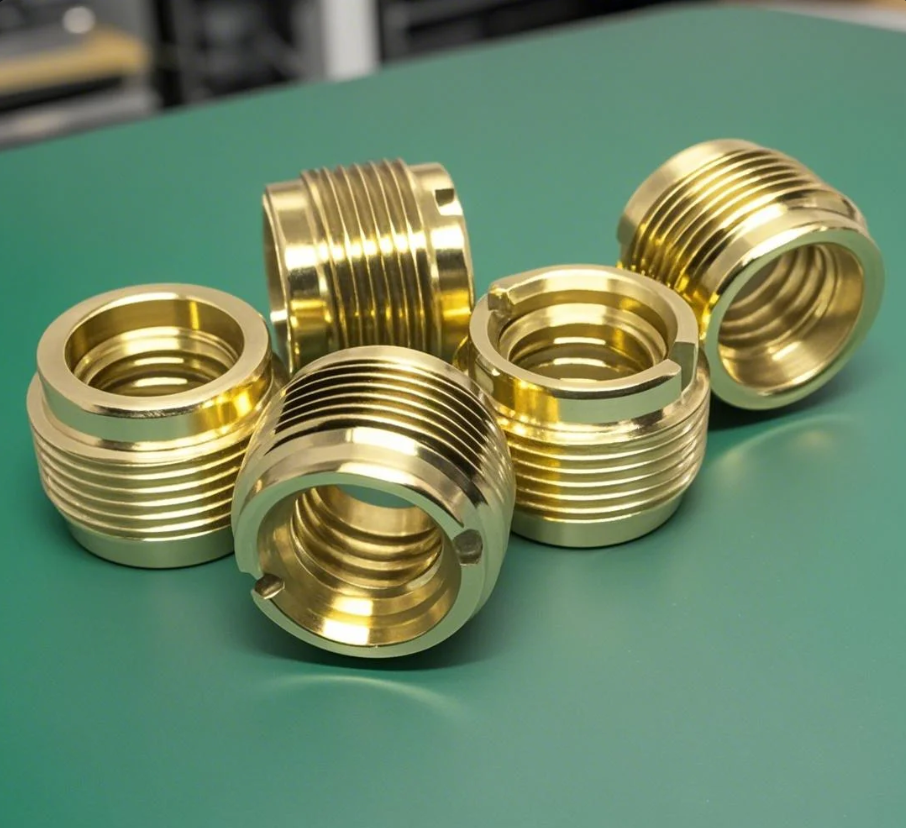

Using premium cutting tools (e.g., carbide end mills) and selecting the right material grade significantly impact tolerances. Our technicians optimize tool paths and cutting parameters to reduce deflection and thermal expansion, ensuring ±.01mm accuracy even for complex geometries.

3. Rigorous Quality Control Protocols

EMAR implements multi-stage inspections, including CMM (Coordinate Measuring Machine) checks and surface roughness tests, to validate every dimension against CAD models. Statistical process control (SPC) further guarantees consistency across batches.

4. Expertise in Programming and Fixturing

Precision starts with flawless G-code programming and secure workpiece fixturing. Our engineers leverage CAM software simulations to preempt errors, while custom jigs eliminate vibration—a common culprit for inaccuracies.

Why Choose EMAR for Precision CNC Machining?

With ISO 9001-certified processes and a track record of serving aerospace, automotive, and medical industries, EMAR combines technology with expertise to deliver unmatched accuracy. Visit our website to explore how we can elevate your project’s precision standards.

By addressing these pillars—machine integrity, tooling, QC, and skilled execution—EMAR ensures your CNC-machined parts meet the tightest tolerances, every time.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque