As a professional CNC Machining service provider, EMAR Company specializes in delivering high-precision mold manufacturing solutions for various industries. Understanding the complete CNC mold machining process flow is essential for procurement managers, engineers, and business owners who demand quality and efficiency in their production.

1. Design and CAD Modeling

The CNC mold machining process begins with precise CAD modeling. Our engineering team converts customer requirements into detailed 3D models using advanced software, ensuring all specifications and tolerances are accurately defined before machining begins.

2. Material Selection and Preparation

We carefully select appropriate materials (typically tool steel, aluminum, or copper alloys) based on the mold's application. The raw material is then cut to size and prepared for machining, with proper consideration given to thermal expansion and stress factors.

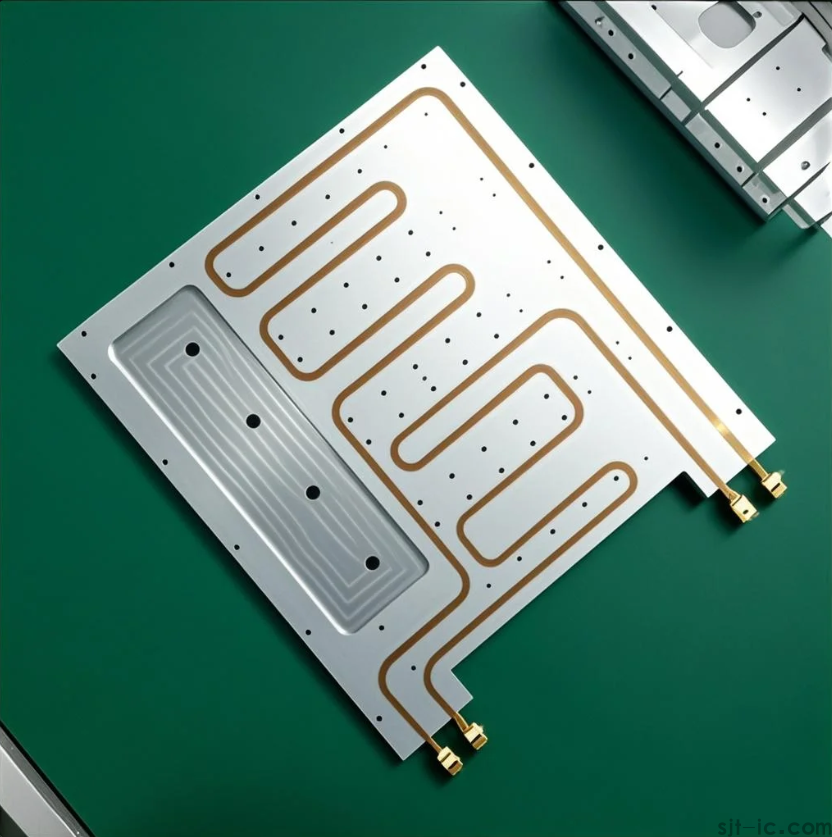

3. CNC Machining Operations

Our state-of-the-art CNC machines perform milling, drilling, and turning operations to shape the mold components with micron-level precision. This stage includes roughing, semi-finishing, and finishing passes to achieve the required surface quality and dimensional accuracy.

4. Heat Treatment and Surface Finishing

Depending on the material and application, molds may undergo heat treatment processes like hardening or tempering. Surface treatments such as polishing, texturing, or coating are applied to enhance durability and performance.

5. Quality Inspection and Testing

Every mold undergoes rigorous inspection using CMM machines, optical comparators, and other precision measuring instruments. We verify all critical dimensions, surface finishes, and functional characteristics before final assembly.

6. Assembly and Final Testing

The completed mold components are assembled and tested under production-like conditions. Our technicians ensure proper alignment, smooth operation, and verify that the mold produces parts meeting all specifications.

At EMAR Company, we combine advanced CNC technology with extensive machining expertise to deliver molds with exceptional precision and longevity. Our comprehensive quality control measures at each stage of the process ensure reliable performance in your production environment.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque