As a professional CNC mold processing provider, EMAR Company understands the critical factors that ensure precision and efficiency in manufacturing molds. This article will explore key considerations to achieve optimal results in CNC mold machining.

Material Selection for CNC Mold Processing

The choice of material significantly impacts the quality and durability of molds. Common materials include tool steel, aluminum alloys, and stainless steel. Each material has unique properties affecting machinability, heat resistance, and surface finish requirements.

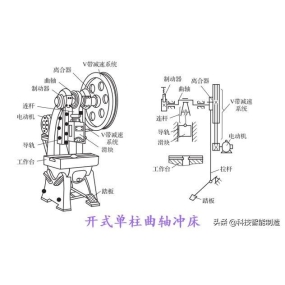

Precision Requirements in Mold Manufacturing

CNC mold processing demands exceptionally tight tolerances, often within ±.01mm. Maintaining this level of precision requires:

- High-accuracy CNC machines with rigid structures

- Proper tool selection and maintenance

- Stable environmental conditions (temperature/humidity control)

- Advanced measurement and inspection equipment

Surface Finish Considerations

The surface quality of molds directly affects product appearance and demolding performance. Key factors include:

- Appropriate cutting parameters (speed, feed rate, depth of cut)

- Tool path optimization to minimize visible tool marks

- Post-processing techniques (polishing, EDM, etc.)

Cooling System Design Integration

Effective cooling channels are crucial for mold performance and longevity. CNC Machining must precisely create these complex internal geometries while maintaining structural integrity.

EMAR's Expertise in CNC Mold Processing

With years of experience in precision machining, EMAR Company offers:

- State-of-the-art 5-axis CNC machines for complex geometries

- Strict quality control processes at every production stage

- Customized solutions for various mold applications

- Technical support throughout the product lifecycle

By addressing these critical aspects, EMAR ensures high-quality CNC mold processing that meets the most demanding industry standards. Contact us at www.sjt-ic.com for your precision machining needs.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque