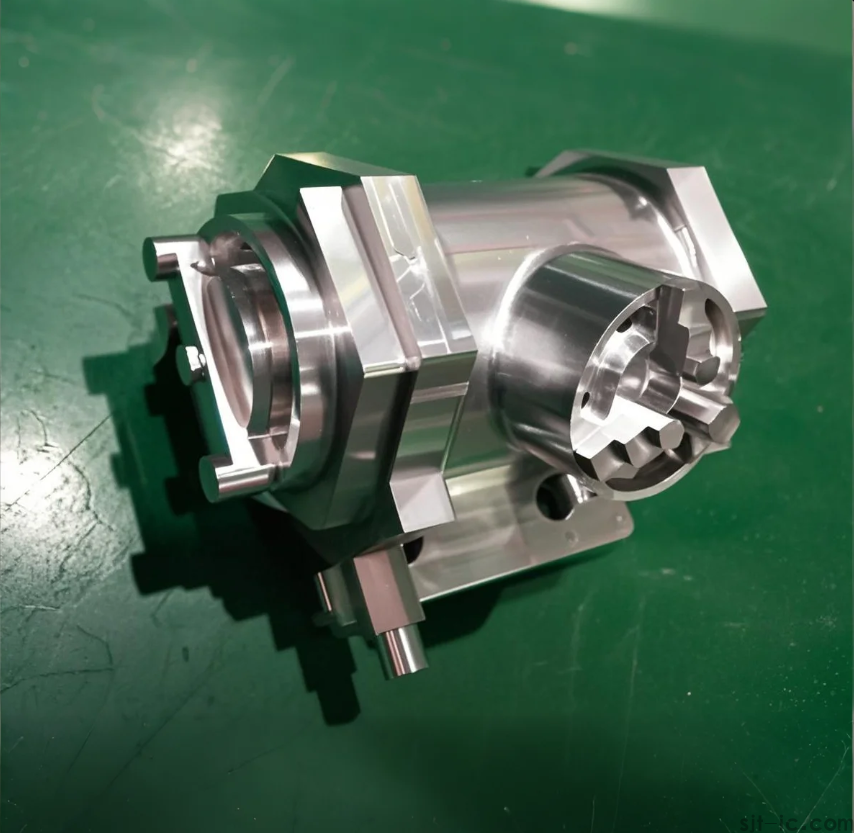

When it comes to CNC custom machining, selecting the right partner is critical for achieving precision, efficiency, and cost-effectiveness. As a leading CNC Machining service provider, EMAR specializes in delivering high-quality, tailored solutions for industries ranging from aerospace to automotive. This article explores key factors to consider when evaluating providers and highlights why EMAR stands out in the competitive landscape.

What Defines a Reliable CNC Custom Machining Provider?

A top-tier CNC machining company should excel in three core areas: technology, expertise, and quality control. EMAR operates state-of-the-art 5-axis CNC machines capable of handling complex geometries with micron-level accuracy. Our ISO 9001-certified processes ensure consistent results, while our engineering team offers 15+ years of experience in material selection and design optimization.

Key Selection Criteria for CNC Custom Services

1. Material Capabilities: EMAR works with 50+ metals/plastics including aluminum, titanium, and PEEK.

2. Turnaround Time: Rush services available with 72-hour delivery for prototypes.

3. Certifications: Compliant with AS910, ITAR, and medical device standards.

4. Value-Added Services: From CAD/CAM support to surface finishing and assembly.

Why EMAR Excels in CNC Custom Machining

Our Shenzhen-based facility combines German-engineered equipment with localized cost advantages, offering 30% faster lead times than European counterparts. Case studies demonstrate our ability to reduce clients' per-unit costs by 18% through design-for-manufacturing analysis. The EMAR Advantage includes 24/7 project monitoring and full documentation traceability.

For organizations prioritizing precision, responsiveness, and total cost management, EMAR delivers end-to-end CNC custom machining solutions backed by a 100% quality guarantee. Contact our engineering team to discuss your project specifications.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque