As a professional CNC Machining service provider, EMAR Company specializes in delivering high-precision custom parts for various industries. Understanding the complete workflow of CNC parts custom manufacturing helps clients optimize their production efficiency and quality control.

Step 1: Design & Technical Review

Our engineers collaborate with clients to analyze 2D/3D drawings or CAD models, ensuring manufacturability and suggesting cost-effective modifications if needed. Material selection (aluminum, steel, titanium, etc.) is finalized based on application requirements.

Step 2: CNC Programming

Using advanced CAM software, our technicians convert designs into machine-readable G-code. Tool paths are simulated to prevent collisions and optimize machining sequences for precision CNC parts production.

Step 3: Machine Setup

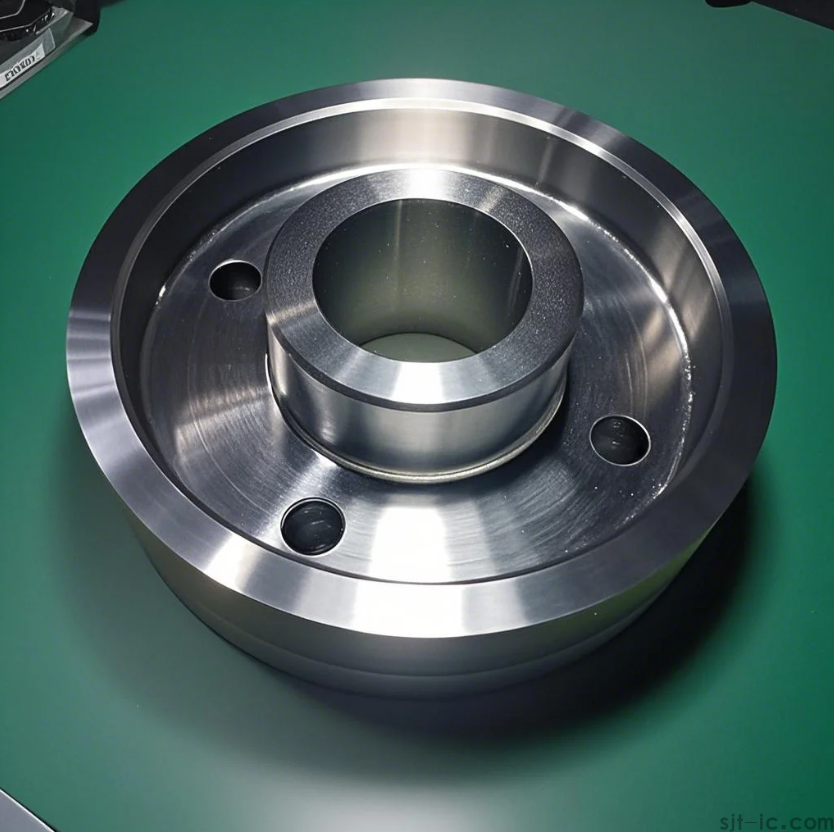

We select appropriate CNC mills/lathes (3/4/5-axis) and calibrate fixtures. Rigorous tool presetting and workpiece alignment ensure ±.01mm repeatability across our 50+ CNC machines.

Step 4: Quality-Centric Production

Real-time monitoring via IoT-enabled equipment guarantees dimensional accuracy. First-article inspection and in-process checks using CMMs verify compliance with ISO 9001 standards.

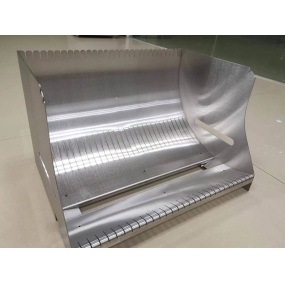

Step 5: Post-Processing & Delivery

Secondary operations (deburring, surface treatment, heat treatment) are performed as specified. Final parts undergo 100% quality certification before secure packaging and logistics arrangement.

EMAR's turnkey solution combines 15+ years of CNC expertise with strict quality protocols, serving aerospace, automotive, and medical industries worldwide. Visit our website to request a free DFM analysis for your project.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque