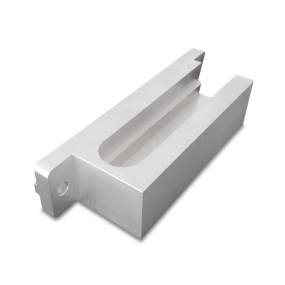

When it comes to CNC mold processing, selecting the right manufacturing partner is critical for precision, efficiency, and cost-effectiveness. As a leading CNC Machining specialist, EMAR Company stands out with advanced technology and proven expertise in mold fabrication.

Key Considerations for Choosing a CNC Mold Processor

1. Precision Capabilities: High-end CNC machines with micron-level accuracy (typically ±.01mm)

2. Material Expertise: Experience with tool steels, aluminum alloys, and engineering plastics

3. Surface Finish Options: Ability to deliver Ra .2μm to 3.2μm as required

4. Quality Assurance: ISO 9001 certification with full inspection reports

Why EMAR Excels in CNC Mold Manufacturing

Our Shenzhen-based facility operates 42 advanced CNC centers (including 5-axis machines) specifically configured for mold processing applications. We offer:

- DFM analysis to optimize mold designs

- High-speed machining for reduced lead times

- EDM and wire-cutting supplementary services

- Complete post-processing (polishing, heat treatment)

Industry-Specific Solutions

EMAR serves diverse sectors requiring precision molds:

• Automotive: Injection molds for interior components

• Electronics: Micro-molds for connectors and housings

• Medical: FDA-compliant tooling for devices

• Consumer Goods: High-cavitation molds for mass production

With 15+ years of experience and 200+ successful mold projects annually, EMAR combines German-engineered equipment with Chinese manufacturing efficiency. Our engineers provide technical consultation throughout your project lifecycle, from prototyping to mass production.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque