Understanding CNC Titanium Alloy Machining

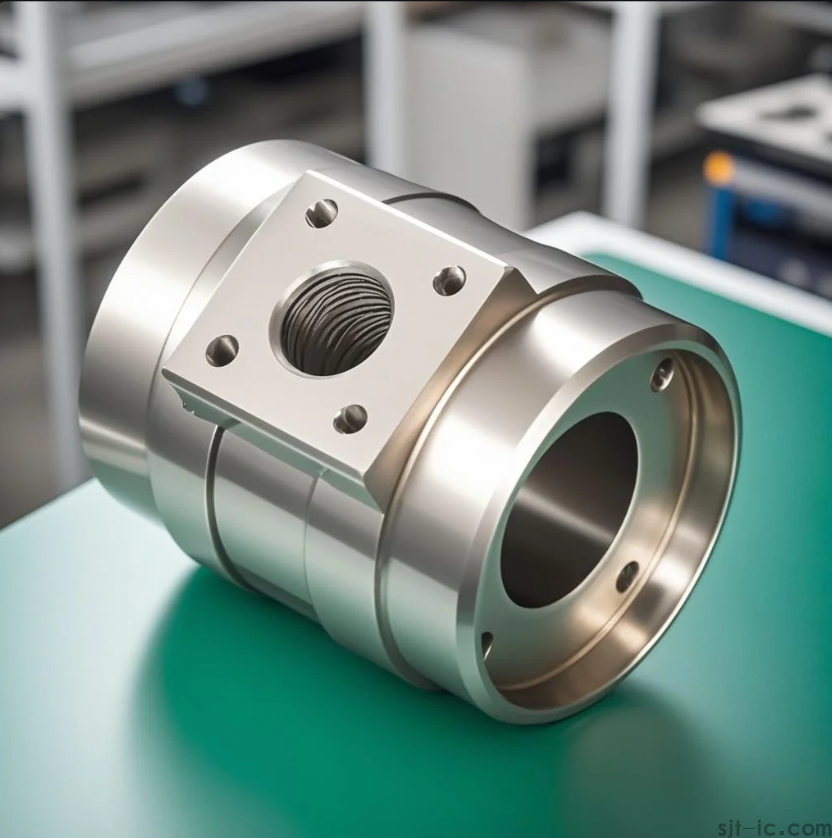

CNC titanium alloy machining is a specialized manufacturing process that requires precision engineering and advanced equipment. As one of the most challenging materials to machine, titanium demands specific techniques to achieve optimal results while maintaining cost-efficiency.

Key Stages in the Process Flow

The complete CNC Machining process for titanium alloys involves several critical stages:

- Material Selection and Preparation

- CAD/CAM Programming

- Machine Setup and Tooling

- Precision Machining Operations

- Quality Inspection

- Surface Treatment (if required)

Technical Challenges and Solutions

Machining titanium alloys presents unique challenges including work hardening, high cutting temperatures, and tool wear. EMAR's approach combines:

- Specialized cutting tools with advanced coatings

- Optimized cutting parameters (speed, feed, depth of cut)

- High-pressure coolant systems

- Rigid machine tool setups

EMAR's Competitive Advantages

Our CNC titanium machining capabilities set us apart through:

- State-of-the-art 5-axis CNC machines specifically configured for titanium

- Experienced metallurgical experts on staff

- Strict quality control protocols meeting aerospace standards

- Efficient production planning for cost-effective titanium machining

Applications Across Industries

Our precision titanium components serve critical applications in:

- Aerospace (structural components, engine parts)

- Medical (implants, surgical instruments)

- Automotive (high-performance racing components)

- Industrial (corrosion-resistant parts)

Partner with EMAR for Your Titanium Machining Needs

With our specialized expertise in titanium machining, EMAR delivers components that meet the most demanding specifications. Contact our engineering team today to discuss your project requirements and benefit from our technical knowledge and manufacturing excellence.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque