As a professional CNC Machining service provider, EMAR Company specializes in delivering high-precision components for various industries. Understanding which parts are best suited for CNC processes is crucial for optimizing production efficiency and cost-effectiveness.

Key Advantages of CNC Machining

CNC (Computer Numerical Control) technology offers unparalleled precision, repeatability, and flexibility in manufacturing. It's particularly suitable for:

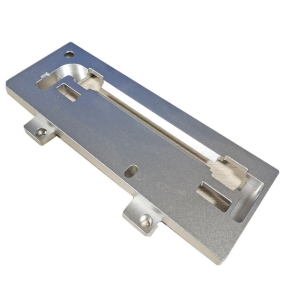

1. Complex Geometrical Components

CNC machines excel at producing parts with intricate designs, tight tolerances, and complex surfaces that would be challenging or impossible with conventional machining methods.

2. High-Volume Production Parts

Once the CNC program is created, identical parts can be manufactured repeatedly with consistent quality, making it ideal for mass production requirements.

3. Precision Engineered Components

Industries such as aerospace, medical, and automotive often require parts with micron-level precision that only CNC machining can reliably deliver.

Common CNC-Compatible Materials

CNC technology works with a wide range of materials including metals (aluminum, steel, titanium), plastics (ABS, PEEK, nylon), and composites, offering versatility across different applications.

Why Choose EMAR for Your CNC Needs?

With advanced CNC equipment and skilled technicians, EMAR Company provides comprehensive machining solutions from prototyping to full-scale production, ensuring quality and efficiency at every stage.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque