When sourcing CNC copper parts machining services, manufacturers and engineers face critical decisions that impact product quality, lead time, and cost efficiency. As an ISO-certified CNC Machining specialist, EMAR offers comprehensive solutions for precision copper components across industries.

Key Considerations for CNC Copper Machining

Copper's unique properties - excellent conductivity, thermal resistance, and corrosion resistance - demand specialized machining expertise. Our CNC copper machining process addresses:

- Material-specific tooling selection to prevent galling

- Optimized cutting parameters for superior surface finishes

- Precision cooling systems to manage heat dissipation

- Dimensional accuracy within ±.005mm

Why EMAR Stands Out in Copper Component Manufacturing

With 15+ years of CNC machining experience, we deliver:

- 50+ advanced CNC mills/lathes with live tooling capabilities

- Material certifications for C11000, C10100, and other copper alloys

- Secondary services including deburring, polishing, and plating

- Prototype to mass production with 98% on-time delivery

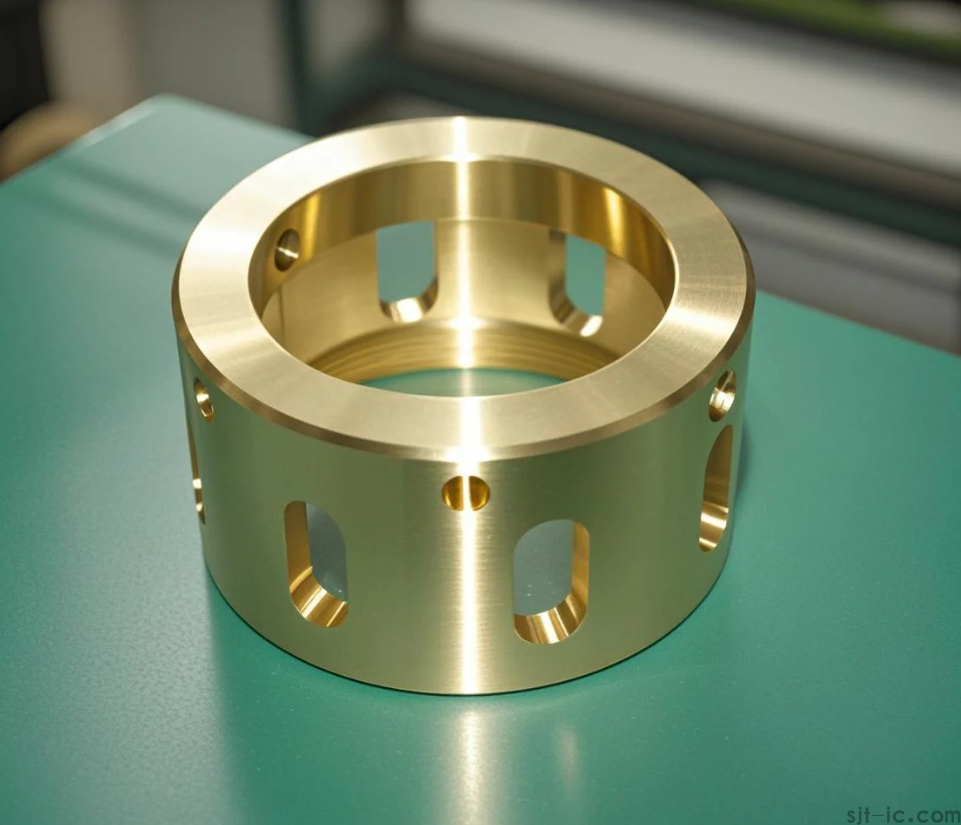

Industry Applications of Our CNC Copper Parts

Our precision-machined copper components serve critical functions in:

- Electrical: Busbars, connectors, and heat sinks

- Automotive: Welding nozzles and bearing cages

- Medical: MRI components and surgical instruments

- Aerospace: Waveguide components and thermal management systems

EMAR's engineering team provides DFM analysis and rapid prototyping to ensure your copper parts meet exact specifications while optimizing manufacturability. Request a free project review via our website or contact our technical specialists today.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque