When it comes to CNC Machining, selecting the right manufacturer is crucial for ensuring precision, efficiency, and cost-effectiveness. EMAR Company specializes in high-quality CNC machining services, catering to industries ranging from aerospace to automotive. But what makes a CNC machining provider stand out? Let’s explore the key factors to consider.

What to Look for in a CNC Machining Provider

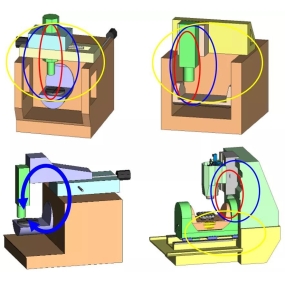

1. Precision and Technology: The best CNC machining companies utilize advanced equipment like multi-axis CNC mills and lathes to deliver micron-level accuracy. EMAR invests in state-of-the-art machinery to meet tight tolerances.

2. Material Expertise: Whether you need aluminum, titanium, or engineering plastics, a top-tier provider should handle diverse materials with consistency.

3. Quality Certifications: ISO 9001 or AS910 certifications are indicators of a commitment to quality control.

4. Turnaround Time: Reliable manufacturers optimize workflows to meet urgent deadlines without compromising quality.

Why Choose EMAR for CNC Machining?

EMAR combines cutting-edge technology with decades of experience to offer:

- Custom CNC milling and turning services

- Prototyping to large-scale production

- Strict quality inspections (CMM measuring, surface roughness tests)

- Competitive pricing and DFM (Design for Manufacturing) feedback

Visit our website www.sjt-ic.com to explore case studies and request a quote.

Industry Applications of CNC Machining

From medical devices to automotive components, CNC machining ensures durability and precision. EMAR’s clients benefit from:

- Complex geometries with 5-axis machining

- High-volume production with zero defect targets

- Post-processing options (anodizing, powder coating)

In summary, the "best" CNC machining partner balances technology, expertise, and customer service. EMAR’s proven track record makes it a trusted choice for global clients. Contact us today to discuss your project requirements!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque