When selecting a CNC Machining service provider, professionals need to consider multiple critical factors to ensure quality, precision, and cost-effectiveness. As an industry-leading CNC machining manufacturer, EMAR provides comprehensive solutions for aluminum, steel, titanium, and various engineering plastics.

Key Considerations for Selecting CNC Machining Services

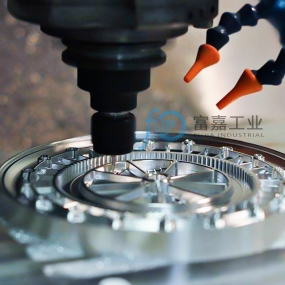

1. Technical Capabilities: Evaluate the provider's equipment portfolio including 3-axis, 4-axis, and 5-axis CNC machines. EMAR operates advanced DMG MORI and Mazak machining centers with ±.005mm tolerance.

2. Material Expertise: Verify experience with your specific materials - we specialize in aerospace-grade aluminum (6061-T6, 7075), stainless steel (303, 304, 316), and engineering plastics (PEEK, Delrin).

3. Quality Certifications: ISO 9001:2015 and AS910D certified facility with complete inspection equipment including CMM and optical comparators.

EMAR's Competitive Advantages

• 15+ years of precision CNC machining experience

• 50,000+ successful projects completed

• 98.7% on-time delivery rate

• 24/7 engineering support

• Competitive pricing with volume discounts

Industry-Specific Solutions

We provide specialized CNC services for:

- Aerospace components (ISO 2768 fine tolerance)

- Automotive prototypes (GD&T compliant)

- Medical device manufacturing (cleanroom available)

- Electronics enclosures (EMI/RFI shielding solutions)

Streamlined Project Process

1. DFM analysis within 24 hours

2. Rapid prototyping (3-5 business days)

3. Production lead time as fast as 10 days

4. Comprehensive quality reports

5. Global logistics support

Contact EMAR today for your CNC machining requirements at www.sjt-ic.com or request an instant quote through our online platform.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque