When it comes to CNC Machining customization, selecting the right partner is critical for achieving precision, efficiency, and cost-effectiveness. As a leading CNC machining service provider, EMAR specializes in delivering high-quality custom solutions for industries ranging from aerospace to medical devices. This guide will help you evaluate key factors when choosing a CNC machining partner.

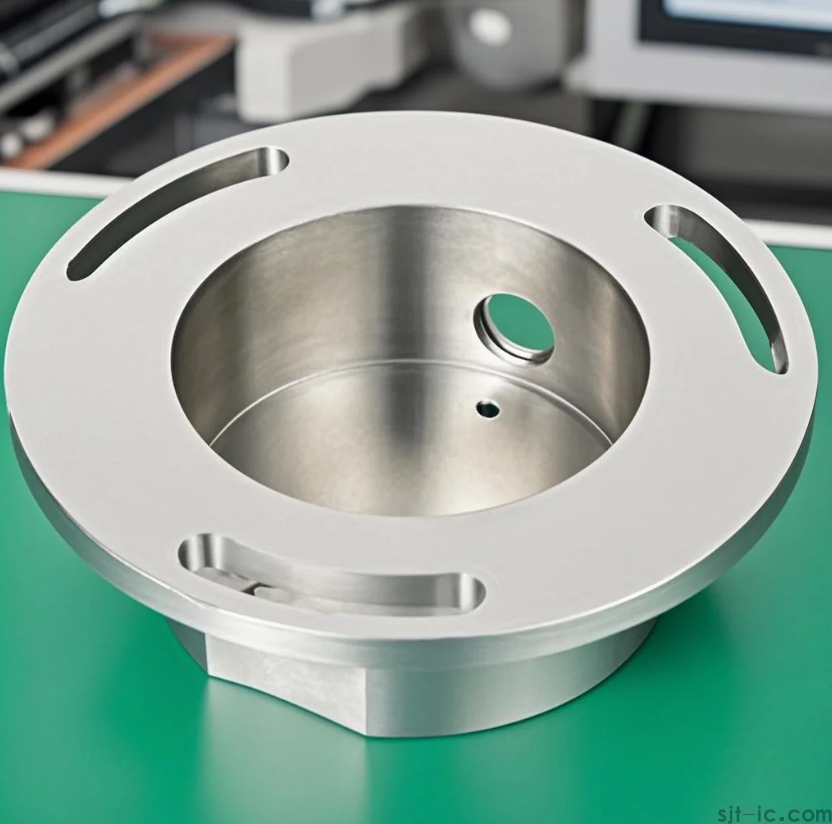

1. Technical Capabilities and Equipment

Top-tier providers like EMAR invest in advanced multi-axis CNC machines (3/4/5-axis), Swiss-type lathes, and precision grinding equipment. Verify if the supplier can handle your material requirements (e.g., aluminum alloys, titanium, or engineering plastics) and tolerances (±.001" or tighter). Our facility features ISO 9001-certified processes with in-house CMM inspection.

2. Industry-Specific Expertise

Different sectors demand unique approaches. For medical components, we implement cleanroom machining and biocompatible surface treatments. Automotive clients benefit from our high-volume production cells with automated quality checks. Review the supplier's portfolio for relevant case studies.

3. End-to-End Service Model

The best providers offer comprehensive services including:

- DFM (Design for Manufacturability) analysis

- Material sourcing and inventory management

- Secondary operations (anodizing, heat treatment, etc.)

- Just-in-time delivery programs

4. Quality Assurance Protocols

EMAR implements a rigorous quality control system featuring:

- First-article inspection reports (FAIR)

- Statistical process control (SPC)

- Material traceability documentation

- Surface roughness measurement (Ra .2μm achievable)

5. Responsive Customer Support

Look for providers with dedicated project managers who offer technical consultations, real-time production updates, and rapid prototyping services (as fast as 24-hour turnaround). Our global clients appreciate our 24/7 engineering support and ERP system integration.

With over 15 years of CNC machining experience, EMAR combines German-engineered equipment with American quality standards to deliver precision components. Contact our team for a free project evaluation and discover why leading manufacturers trust us for their most demanding custom machining requirements.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque