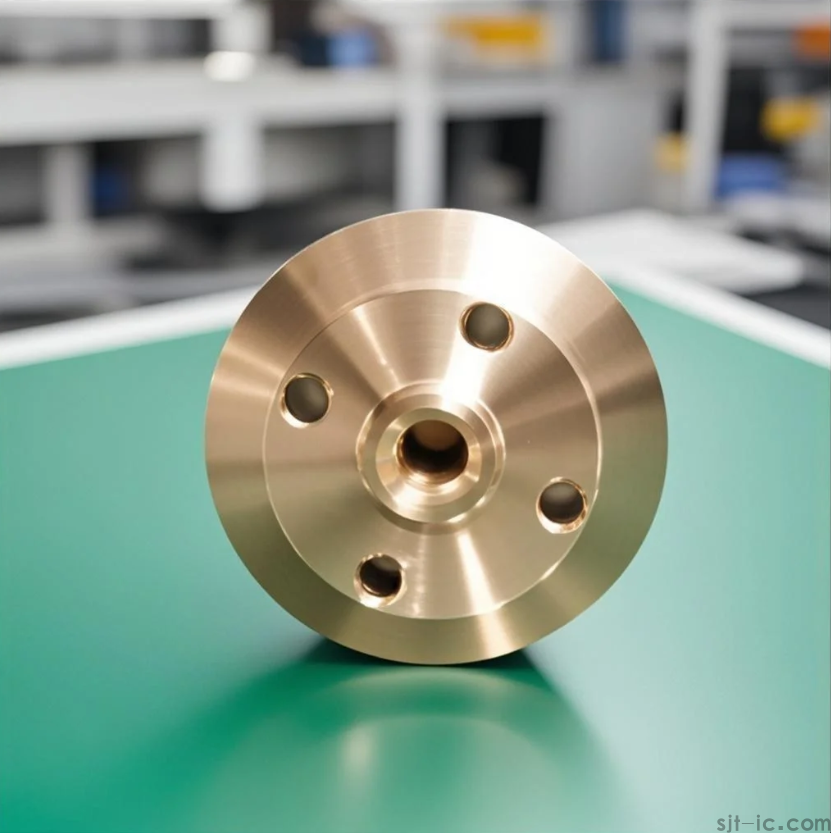

As a leading CNC Machining manufacturer, EMAR specializes in high-quality copper CNC machining production for industries requiring superior conductivity, corrosion resistance, and thermal performance. This guide explores the technical nuances of machining copper alloys and how our capabilities address critical manufacturing challenges.

Why Choose Copper for CNC Machining?

Copper's unique properties make it indispensable for electrical components, heat exchangers, and precision instruments. Our CNC machining processes optimize copper's soft yet gummy characteristics through:

- Specialized tool geometries to prevent material adhesion

- Optimized cutting parameters (speeds/feeds) for chip control

- Custom coolant strategies to maintain dimensional stability

EMAR's Copper Machining Capabilities

Our 5-axis CNC centers achieve ±.005mm tolerances on copper parts, supported by:

- Dedicated copper machining workstations with vibration damping

- In-process inspection using laser measurement systems

- Post-machining treatments including passivation and ESD protection

Industry-Specific Solutions

We deliver copper components for:

- Electrical: Busbars, connectors, and RF shielding

- Thermal Management: Heat sinks and cooling jackets

- Industrial: Bearing sleeves and wear components

Quality Assurance Protocol

Every copper part undergoes:

- Material certification (ASTM B152/B187)

- Conductivity testing (4-point probe method)

- 3D scanning against CAD models

With ISO 9001-certified processes and DFM support, EMAR ensures your copper components meet exact specifications while optimizing production efficiency. Contact our engineering team at www.sjt-ic.com for project consultation.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque