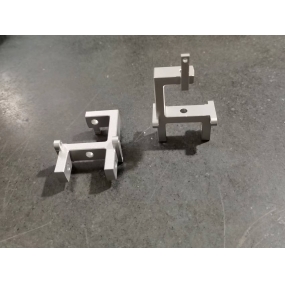

As a leading CNC Machining service provider, EMAR specializes in delivering exceptional precision components for industries requiring tight tolerances and superior surface finishes.

Understanding CNC High-Precision Machining

CNC high-precision machining refers to manufacturing processes that achieve tolerances within ±.001" to ±.0001" (.025mm to .0025mm), utilizing advanced computer-controlled equipment, premium tooling, and rigorous quality control measures.

Key Advantages of Our Process

1. Micro-Level Accuracy: Our 5-axis CNC machines maintain positional accuracy within 5μm

2. Superior Surface Quality: Achieve Ra .2μm surface finishes without secondary processing

3. Material Versatility: Expertise in machining aerospace alloys, medical-grade materials, and engineering plastics

Our Technical Capabilities

EMAR's high-precision CNC machining facility features:

- 20+ CNC machining centers with thermal compensation systems

- In-process measurement with laser scanning technology

- Climate-controlled production environment (±1°C regulation)

Quality Assurance Protocol

Every precision component undergoes:

1. First-article inspection with CMM (Coordinate Measuring Machine)

2. Statistical process control during production runs

3. Final inspection against ASME Y14.5 GD&T standards

For mission-critical components requiring exceptional dimensional stability and repeatability, trust EMAR's certified CNC high-precision machining solutions. Contact our engineering team for project consultation.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque