As a leading CNC Machining service provider, EMAR Company understands that cost calculation is a critical concern for procurement managers and engineers. This guide will break down the key factors influencing CNC machining costs and how we optimize value for our clients.

Key Factors Affecting CNC Machining Costs

The CNC machining cost calculation method typically considers these elements:

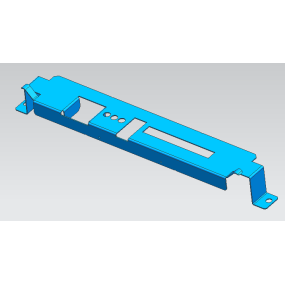

Material type and quantity

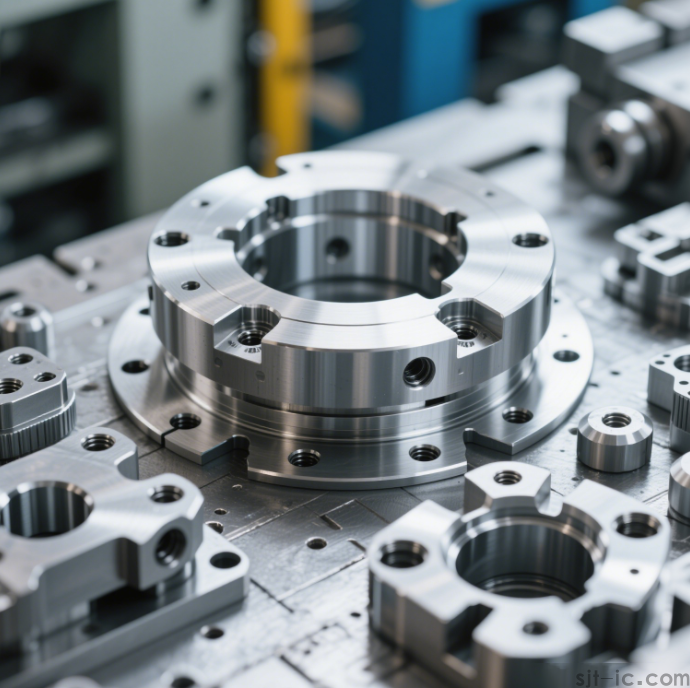

Part complexity and tolerances

Machine time and labor costs

Surface finishing requirements

Order quantity and repeat orders

How EMAR Optimizes Your Machining Costs

Our CNC machining experts employ advanced strategies to reduce your expenses:

Material optimization through nesting software

Efficient toolpath programming to minimize machine time

Bulk purchasing discounts passed to clients

Value engineering suggestions during DFM analysis

Transparent Pricing Structure

Unlike competitors with hidden fees, EMAR provides clear breakdowns in our CNC machining cost calculation method:

Material cost: Calculated per part based on consumption

Machine time: Hourly rate based on equipment type

Setup charges: One-time fee per production run

Finishing costs: Additional processes quoted separately

Contact our technical team today for a free project evaluation and precise cost estimation tailored to your specific requirements.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque