As a leading CNC Machining service provider, EMAR understands that CNC machining cost estimation is a critical concern for procurement managers and engineers. This guide breaks down the key factors affecting pricing and how our company delivers competitive value.

Key Factors Influencing CNC Machining Costs

1. Material Selection: Aluminum alloys typically cost 20-30% less than titanium or stainless steel machining

2. Part Complexity: Complex geometries requiring 5-axis machining increase costs by 40-60% compared to standard 3-axis work

3. Production Volume: Unit costs decrease significantly for orders over 500 pieces due to optimized tool paths and setup amortization

EMAR's Transparent Pricing Approach

We employ industry-leading CNC machining cost calculation software that considers:

- Machine time (including tool wear compensation)

- Material waste percentage

- Post-processing requirements (anodizing, polishing, etc.)

- Quality inspection protocols

Cost-Saving Strategies We Implement

1. Design for Manufacturability analysis during quoting phase

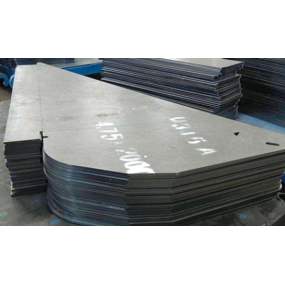

2. Multi-part nesting optimization for material utilization

3. Bulk purchasing discounts passed directly to clients

4. Alternative material suggestions meeting specifications at lower cost

Visit EMAR's official website to request a detailed quote with our proprietary cost breakdown format, showing exactly where your budget is allocated.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque