Feeling confused by CNC Machining quotes? 🤔 You're not alone. One day you get a surprisingly low number, and the next, a sky-high estimate for what seems like a similar part. It's enough to make any project manager or business owner scratch their head. If you've ever wondered, "How on earth is CNC machining cost actually calculated?", you've come to the right place. Let's pull back the curtain together and break down the real factors that determine your final bill. 💰

So, What's the Real Formula for CNC Machining Cost?

Let's get straight to the point. There isn't one single, magical formula that fits every project. Instead, the cost is a total of several key parts working together. Think of it like baking a cake—you need to account for the ingredients (material), the time and skill of the baker (machine and labor time), and any special decorations (post-processing). Here are the main "ingredients" that go into your quote:

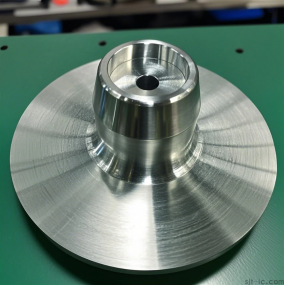

1. Machine Time: This is often the biggest chunk. It's the time the CNC machine spends actually cutting your part. More complex designs and tougher materials mean longer machine time.

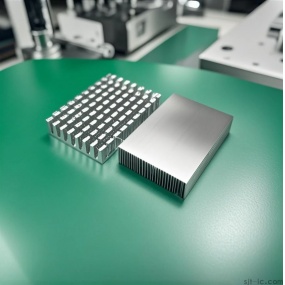

2. Material Cost: The raw block of metal or plastic you start with isn't free. Aluminum is common and relatively affordable, while exotic alloys like titanium will cost you more.

3. Setup Time: Before any cutting happens, a technician needs to set up the machine, install the right tools, and secure the material. This is a fixed cost per order.

4. Post-Processing: Does your part need a smooth finish? Anodizing? Painting? These extra steps add to the cost.

Wait, How Does Part Design Actually Affect the Price?

You might be surprised how much your design choices matter. A simple block with a few holes is cheap. But if your design has complex curves, super tight tolerances, or super thin walls, the price can jump up. Why? Because it forces the machine to slow down, might require special tools, and takes more skill from the operator. It's a classic case of "more complexity = more time and money".

However, it's worth mentioning that the specific impact of a single design feature, like a particular internal corner radius, can be tricky to isolate in the total cost. The exact way it influences machining strategy and time might need a deeper look on a case-by-case basis.

Is a Cheaper Quote Always a Better Deal?

This is the million-dollar question, isn't it? On the surface, a lower price is tempting. But hold on. A quote that's significantly lower than others might be a red flag. 🚩 The supplier might be using lower-grade material, or maybe they've underestimated the machine time and will hit you with extra charges later.

I've found that the most reliable shops provide detailed, transparent quotes that break down the costs. This shows they understand your project thoroughly. Perhaps this suggests that prioritizing clarity and communication is just as important as the final number itself.

A Quick Tip from My Desk

One thing I always do when getting a quote is to ask if there's any way to tweak the design to save cost without hurting the part's function. Sometimes, slightly relaxing a non-critical tolerance or changing a deep pocket can lead to significant savings. It never hurts to ask! A good machining partner will work with you on this.

At the end of the day, understanding the "how" behind CNC machining costs puts you in the driver's seat. It allows for smarter budgeting and helps you build a stronger, more transparent relationship with your manufacturing partners.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque