Hey there, fellow procurement pros and engineers! 👋 Are you tired of sourcing stainless steel parts that almost meet your specs, but then cause headaches down the line with fit, finish, or failure? You're not alone. Getting custom CNC turning right, especially with tricky materials like stainless steel, feels like a high-stakes puzzle. But what if you had a clear map? This guide cuts through the confusion and lays out exactly what you need to know.

What Exactly is Custom Stainless Steel CNC Turning?

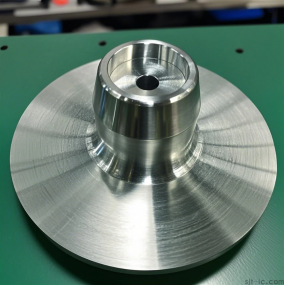

Let's break it down. Imagine a super-precise, computerized lathe spinning a block of stainless steel. Now, imagine cutting tools, controlled by digital blueprints (your CAD file!), sculpting that spinning metal into the exact part you designed. That's the core of it. It's a subtractive process – meaning we start with a solid and remove material to create the shape. The "custom" part is all about your unique requirements: the specific dimensions, the tight tolerances, the surface texture, and those special threads or grooves that make your project work.

Why Pick Stainless Steel for Your Custom Parts? 🤔

Stainless steel isn't just shiny; it's a workhorse. Here’s why it’s a go-to for so many of us:

✔️ Tough as Nails: It's famous for its strength and resistance to wear and tear. Parts last longer, which is what we all want.

✔️ Rust? What Rust? The chromium in stainless steel forms an invisible shield, making it highly resistant to corrosion. Perfect for harsh environments or medical applications.

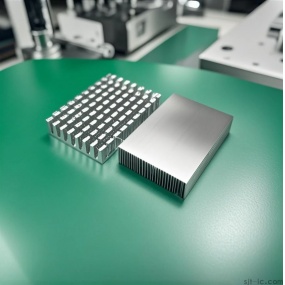

✔️ It Just Looks Professional: A clean, polished finish on stainless steel gives a quality feel that clients and end-users notice.

But, here's the thing... While stainless is fantastic, its toughness also makes it a bit more challenging to machine compared to, say, aluminum. It requires the right tools and expertise, which can perhaps suggest a slightly higher cost. It's a trade-off for performance.

Key Questions to Ask Before You Order

Don't just send a drawing and hope for the best. Being proactive saves time and money. I always ask my suppliers these questions:

🔹 What's your experience with a grade like 304 or 316 stainless? (Their answer tells you a lot).

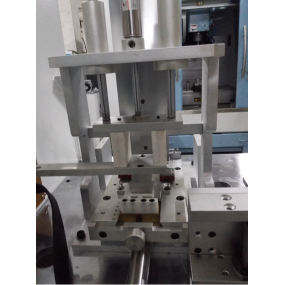

🔹 How do you handle quality checks during production? Look for answers about first-article inspection and process control.

🔹 What are my options for surface finishes? From a basic mill finish to a mirror polish, your choice affects both look and cost.

One area I'm less clear on is the exact science behind optimal cutting fluid formulations for different stainless steel alloys. The specific mechanisms for maximizing tool life and surface finish in real-time are something I know suppliers constantly refine through experience.

Navigating the Ordering Process Smoothly

Okay, so you're ready to go. Here's a typical flow I use:

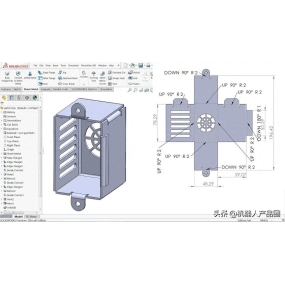

1. Share Your Vision: Send over your technical drawing (PDF is great) and, if you have it, a 3D CAD model. The more detail, the better.

2. Get the Quote: The supplier will review your files for manufacturability. They might suggest small tweaks to save you money – listen to them!

3. Prototype & Approval: For a new part, always get a first article to check. Hold it in your hands, test it.

4. Full Production: Once you give the thumbs-up, they'll ramp up to your full order quantity.

However, it's worth mentioning that this process can hit snags if communication isn't clear. A five-minute call can sometimes prevent a week of delays.

My Take: It's More Than Just a Part

In my years of doing this, I've learned that ordering custom machined parts isn't a simple transaction. It's a partnership. The best outcomes come from working with your supplier, not just throwing specs over a wall. A good supplier becomes an extension of your team, helping you solve problems you didn't even know you had. So, invest time in finding a partner who gets it. Your future self, enjoying a smooth production run with zero defective parts, will thank you. 🚀

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque