Hey there, fellow engineers and procurement pros! 👋 Are you tired of sourcing CNC guide pillars that just don't meet the mark? You know, the ones that promise precision but deliver headaches with premature wear or poor fit? You're not alone. Getting the processing techniques right is the absolute key to performance and longevity. So, what exactly goes into a top-quality CNC guide pillar? Let's dive right in and unpack the process from raw material to finished product. I've been around the block a few times with this, and I'm hoping my experience can shed some light for you.

What is CNC Guide Pillar Processing Anyway? 🤔

At its heart, it's all about using computer-controlled machines to carve a super precise cylindrical pin from a metal bar. This isn't your grandpa's lathe work. We're talking about creating a critical component that guides moving parts in molds and machinery with zero wobble. The main goal? To achieve a surface that's mirror-smooth, dimensions that are spot-on, and a hardness that can take a beating. If any of these are off, the whole assembly can suffer. It's the foundation of smooth operation.

The Core Steps in the Manufacturing Process

While the exact sequence can vary from shop to shop, the journey usually follows these key stages. I'll walk you through what I typically look for:

1. Material Selection: It all starts with the right steel. Most high-quality guide pillars are made from bearing steel or carburizing steel. Choosing the wrong material here is a recipe for disaster down the line.

2. Rough Machining (CNC Turning): This is where the bulk of the material gets removed. A CNC lathe shapes the rough bar to get it close to the final dimensions, but leaves a little extra room—what we call "machining allowance"—for the finishing touches.

3. Heat Treatment: This is the magic step that gives the pillar its strength and wear resistance. The part is heated and cooled under strict control to harden its surface. However, it's worth noting that the specific time-temperature profile for maximizing toughness without inducing brittleness can be a complex trade-off.

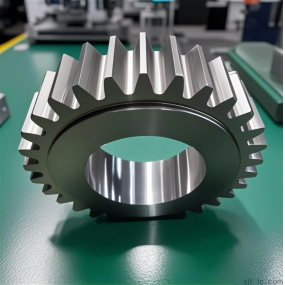

4. Precision Grinding: After heat treatment, the part is harder but might have warped slightly. This is where precision grinding comes in. Using specialized grinding wheels, the pillar is brought to its exact final diameter and a super fine surface finish. This step is non-negotiable for achieving the required fit.

5. Surface Enhancement (Hard Chrome Plating & Polishing): Finally, a layer of hard chrome is often applied. This adds an extra shield against corrosion and wear. Then, it's polished to a mirror-like shine, which minimizes friction. This final finish is what really makes a part look and feel professional.

Why Tolerances and Surface Finish Aren't Just Numbers

We all see these specs on drawings, but what do they really mean on the shop floor? A tight tolerance ensures the guide pillar slides into its bushing with a perfect, predictable gap—not too tight to bind, not too loose to clunk. That perfect fit is what eliminates play and vibration. Similarly, a superior surface finish does more than just look good. It actually creates a surface that can better retain lubricant, reducing friction and heat buildup. In my view, this is where you separate the average suppliers from the exceptional ones. Spending a little more here can save a fortune on downtime.

Common Hurdles and What to Watch Out For

Even with a great process, things can go wrong. Let's be honest about a few common pitfalls:

• Internal Stresses Causing Warping: Sometimes, stresses locked inside the raw material can be released during machining, leading to warping after the fact. This might indicate a problem with the initial material quality or the rough machining parameters.

• Grinding Burns: If the grinding step is too aggressive, it can generate excessive heat and literally "burn" the surface of the steel, creating a weakened layer that can spall off later. A good supplier has strict controls to prevent this.

• The Plating Puzzle: Achieving a uniform, adherent chrome plate is a art in itself. Poor adhesion can lead to flaking. To be completely transparent, the exact electrochemical mechanisms that guarantee perfect adhesion every time are still a bit of a black box to me, and often come down to a supplier's proprietary experience.

Anyway, the key takeaway is that a reliable manufacturer will have quality checks at every stage to catch these issues before the part ever ships.

From my experience, the real cost isn't in the price per piece, but in the total cost of ownership. A well-made guide pillar, produced with the right CNC guide pillar processing techniques, might cost a few dollars more upfront, but it will outlast cheaper alternatives by a wide margin, protecting your machinery and your production schedule. It's an investment in peace of mind. 🚀

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque