Hey there, fellow engineers and procurement pros! 👋 Ever been stuck in a project because your motor gears just aren't cutting it? Maybe they're too noisy, don't fit right, or worse – fail way too early. We've all been there. It's frustrating, right? When precision is everything, the way your gears are made makes all the difference. So, what's the go-to method for getting it right? Let's talk about why CNC Machining is often the answer for motor gears.

What's the Big Deal with CNC for Motor Gears Anyway?

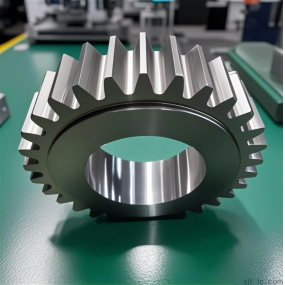

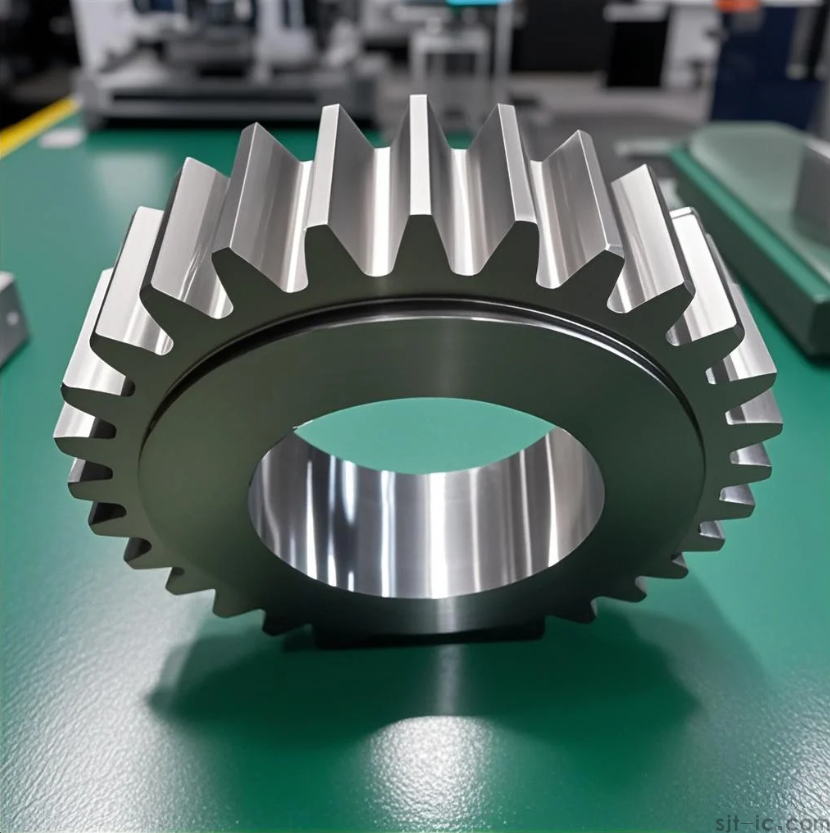

At its heart, this is about control. Think of CNC (Computer Numerical Control) as a super-skilled robotic craftsman. You give it a digital blueprint, and it follows those instructions to the letter, cutting metal with crazy accuracy. For motor gears – those critical parts that transfer motion and power – this precision isn't just a nice-to-have; it's essential. It means every tooth, every curve, is exactly as designed, which leads to smoother operation, less wear and tear, and a longer life for your whole motor assembly. While other methods exist, CNC brings a level of consistency that's hard to beat.

Benefit 1: Unbeatable Precision and Consistency

This is the number one reason people turn to CNC.

• Spot-On Every Time: Once the program is set, the machine produces near-identical parts, one after the other. This eliminates the tiny variations that can cause big problems in a tightly packed gearbox.

• Tight Tolerances: We're talking about accuracy within a few microns. This is crucial for ensuring gears mesh perfectly without backlash or binding.

I've seen projects transformed simply by switching to a reliable CNC supplier. The reduction in assembly line issues was dramatic. 🎯

Benefit 2: It's a Speed Demon for Production

In our fast-paced world, time is money.

• Quick Turnaround: After the initial setup, CNC machines can run 24/7, churning out parts much faster than manual machining.

• From Prototype to Mass Production: The same digital file used for a one-off prototype can be used for a production run of thousands. This seamless scaling is a huge advantage.

This speed can be a lifesaver when you're facing tight deadlines. But, to be completely honest, the specific programming and toolpath optimization for complex gear geometries can sometimes add to the initial setup time. It's a bit of a front-loaded effort.

Benefit 3: Mind-Blowing Material Flexibility

Motor gears aren't one-size-fits-all, and neither should be your manufacturing process.

• Works with Almost Anything: Whether you need the strength of steel, the lightness of aluminum, or the special properties of engineering plastics like POM or Nylon, a CNC machine can handle it.

• Material Properties Matter: This flexibility lets you choose the perfect material for the job – considering factors like load, temperature, and required lifespan.

Benefit 4: Complex Designs? No Sweat.

Modern motors often demand unconventional gear shapes for optimal performance.

• Beyond Simple Gears: Helical gears, bevel gears, worm wheels – you name it. CNC machining can create these complex geometries with ease.

• Integrated Features: It can even machine the gear and its shaft as a single piece, reducing assembly steps and potential failure points.

This capability perhaps suggests that the future of compact motor design is heavily reliant on such advanced machining techniques. However, it's worth noting that the exact economic trade-off between complexity and cost for ultra-intricate designs is an area where my expertise gets a bit fuzzy; it often depends on the specific application.

Benefit 5: It's Surprisingly Cost-Effective in the Long Run

Yeah, you heard that right. While the initial investment might seem high, look at the bigger picture.

• Less Material Waste: CNC is a subtractive process, but modern programming optimizes the cutting path to use the raw material very efficiently.

• Lower Labor Costs: One operator can oversee multiple machines, and there's less need for constant manual quality checks because the machine is so consistent.

• Fewer Faulty Parts: Higher consistency means fewer rejects, saving you money on wasted materials and rework.

When you add up the savings from reduced waste, less scrap, and higher reliability, the value proposition becomes clear. 💰

So, Is CNC Always the Perfect Choice?

Okay, let's be real. No technology is a magic bullet. For incredibly high-volume production of super simple gears, other methods like stamping or sintering might be more economical. And the expertise required to program the machines for optimal gear cutting is a specialized skill. But for the vast majority of applications where quality, precision, and flexibility are paramount – especially for those in procurement and engineering who can't afford downtime – CNC machining for motor gears is a solid bet. It gives you that peace of mind that the core components of your drive system are built right.

From my own experience, the reliability it brings to the supply chain is often the deciding factor. It's one less thing to worry about when you're trying to get a product out the door.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque