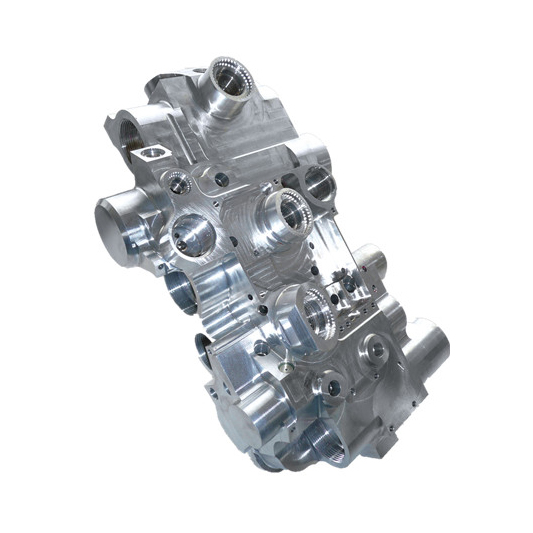

Five axis CNC Machining is a mode of CNC machine tool machining that uses five coordinate axes (three moving axes x, y, z plus two rotating axes A, B, or C) for linked machining. This processing method can efficiently and accurately complete the processing of complex geometric parts, and is commonly used in fields such as aviation, aerospace, automotive, and molds. The technical functions of  CNC five axis machining are mainly reflected in the following aspects: 1. High speed machining function: The five axis linkage CNC system has the ability of high-speed cutting, which can significantly improve machining efficiency. 2. Precision machining function: The system is equipped with precision sensors and measuring devices, which can monitor errors in the machining process in real time and automatically compensate to ensure machining accuracy. In addition, it also has an automatic calibration function, which can automatically adjust the parameters of the machine tool to achieve more precise machining. 3. Multi functional machining function: Five axis machining can achieve various machining operations such as milling, drilling, tapping, turning, etc., to meet the needs of different machining tasks. 4. Automated machining function: Through preset machining programs, five axis machining can achieve functions such as automatic tool changing, automatic measurement, and automatic compensation, reducing operator intervention and improving machining stability and consistency. 5. Multi axis linkage function: Five axis linkage means the coordinated motion of the three moving axes x, y, and z plus any two rotating axes (A, B, or C), which enables the machining tool to be positioned and connected in five degrees of freedom, especially suitable for machining parts with complex geometric shapes.

CNC five axis machining are mainly reflected in the following aspects: 1. High speed machining function: The five axis linkage CNC system has the ability of high-speed cutting, which can significantly improve machining efficiency. 2. Precision machining function: The system is equipped with precision sensors and measuring devices, which can monitor errors in the machining process in real time and automatically compensate to ensure machining accuracy. In addition, it also has an automatic calibration function, which can automatically adjust the parameters of the machine tool to achieve more precise machining. 3. Multi functional machining function: Five axis machining can achieve various machining operations such as milling, drilling, tapping, turning, etc., to meet the needs of different machining tasks. 4. Automated machining function: Through preset machining programs, five axis machining can achieve functions such as automatic tool changing, automatic measurement, and automatic compensation, reducing operator intervention and improving machining stability and consistency. 5. Multi axis linkage function: Five axis linkage means the coordinated motion of the three moving axes x, y, and z plus any two rotating axes (A, B, or C), which enables the machining tool to be positioned and connected in five degrees of freedom, especially suitable for machining parts with complex geometric shapes.

Hello! Welcome to EMAR's website!

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque