Hey there, fellow engineers and procurement pros! 👋 Are you stuck wondering if that pricey high-end CNC machine is really worth the investment over a standard one? You're not alone. I've been in this industry for years, and this is one of the most common yet crucial questions we face. Let's cut through the marketing fluff and get down to the real brass tacks. What exactly are you paying for, and when does it make sense for your shop floor? 🤔

What Exactly Makes a CNC Machine "High-End"?

First things first, let's clear up what we're talking about. When we say "high-end," we're not just talking about a higher price tag. It's about a combination of things that work together.

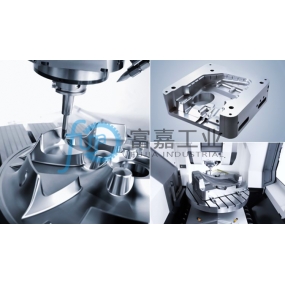

Super-Tight Accuracy and Repeatability: This is the big one. A high-end machine can hold tolerances that are just mind-bogglingly small, think fractions of a human hair. And it does this all day, every day, for part number one and part number one thousand.

Ridiculous Speed and Power: These machines don't just move fast; they accelerate and decelerate with purpose, slashing cycle times. The spindles are more powerful, allowing them to chew through tough materials like titanium without breaking a sweat.

Advanced Software and Controls: The brain of the operation is smarter. It can predict and compensate for things like tool wear, temperature changes, and even vibrations, which is something I'm still trying to fully wrap my head around.

Where a Standard CNC Machine Still Holds Its Ground

Now, before you run off and max out your budget, let's be real. Standard CNC machines are the backbone of many workshops for a reason.

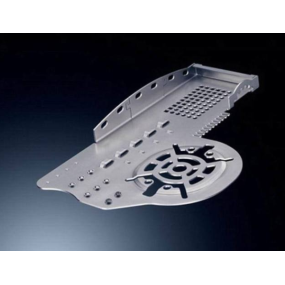

Cost-Effectiveness for Simpler Jobs: If you're mainly working with aluminum or mild steel on parts with looser tolerances, a standard machine might be all you need. Why pay for a Ferrari to drive to the grocery store?

Easier on the Wallet (Initially): The upfront cost is significantly lower. For a startup or a shop with a very specific, unchanging product line, this can be the deciding factor.

But here's the thing... the "easy to use" argument can be a bit misleading. While they might be simpler to learn, the lack of advanced features can sometimes make complex jobs more manual and time-consuming.

The Hidden Costs (and Savings) You Might Not See Coming

This is where it gets interesting. The price tag is just the beginning. Let's talk about the money that flows after the purchase.

Durability and Uptime: High-end machines are often built like tanks. This robust construction typically translates to less downtime over its lifetime. While any machine can break, the mean time between failures on a premium model is often much longer. This perhaps suggests that the total cost of ownership over ten years might be closer than you think.

Energy and Tooling Consumption: This is a tricky one. High-end machines are more powerful, but they are also often more efficient. The specific mechanism of how they balance power draw with faster cycle times to save energy is something that really depends on the job and material.

So, When Should You Seriously Consider the High-End Route?

Based on my experience, here's my personal take. Pull the trigger on a high-end machine when:

✅ You're constantly pushing the limits of your current equipment's precision and capability.

✅ Your business is growing into aerospace, medical, or automotive sectors where quality is non-negotiable.

✅ You're losing money on re-work, scrap parts, or slow production speeds.

Making the jump is less about the machine itself and more about what it enables your business to do and become. It's a tool for growth, not just a cost.

A Final Thought from the Workshop Floor

I've seen shops buy a standard machine and run it perfectly for decades. I've also seen shops struggle because they under-bought. The right choice isn't about which one is "better" in a vacuum. It's about which one is better for you, right now, and for where you want to be in five years. Don't just look at the specs sheet; think about your workflow, your team's skills, and your most ambitious projects. That's where the real answer is hiding. 🛠️

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque