Hey there, are you a project manager or engineer staring at a list of potential high-precision CNC Machining suppliers, feeling a bit stuck? 🤔 You know that picking the wrong partner can lead to delayed projects, wasted budget, and a whole lot of headaches. So, how do you sift through the options and find a reliable partner that actually delivers on their promises? Let's break it down together, step by step.

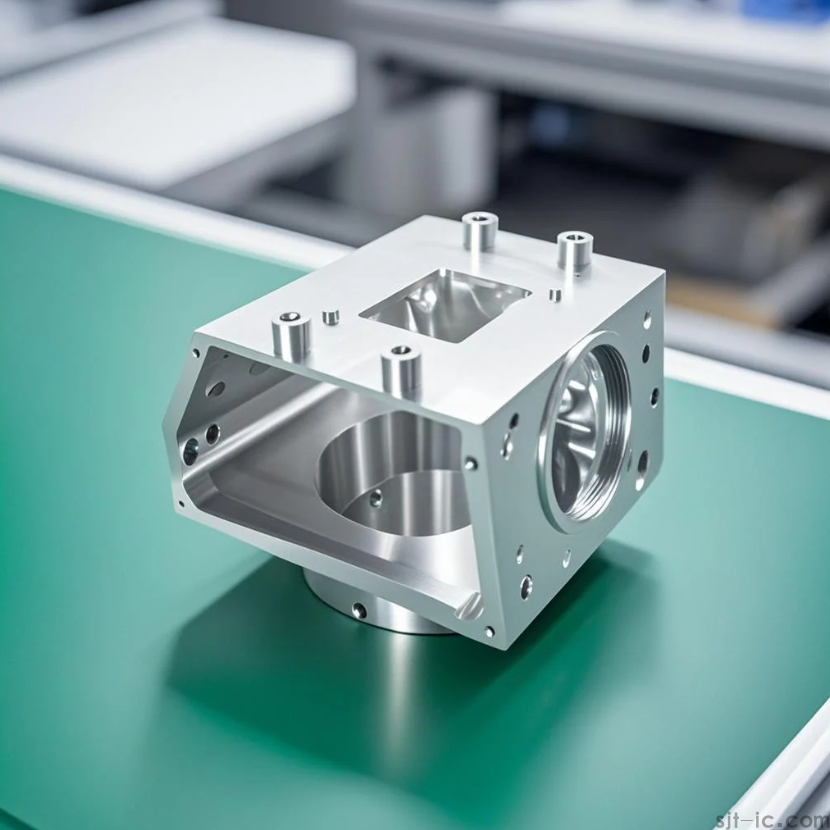

What Exactly Do You Mean by "High-Precision"?

Before you even start looking, you've got to get crystal clear on your own needs. "High-precision" can mean different things to different people. For some, it's about tight tolerances, like within a few microns. For others, it's about the perfect surface finish. I often see folks skipping this step and then getting surprised when the results don't match their vision.

Ask yourself these questions:

• What are the critical dimensions and tolerances for my part?

• What material am I using, and how does it behave during machining?

• What is the expected volume? Is this a one-off prototype or ongoing production?

Getting this down on paper is your first and most important filter. Although, it's worth mentioning that the specific mechanisms of how certain materials react under ultra-high-speed machining can get pretty complex, and that's an area where I lean heavily on the supplier's expertise.

Don't Just Look at the Brochure: Dig Into Their Real Capabilities

Anyone can say they do "high-precision" work. The proof is in the pudding, or in this case, their equipment and track record. A supplier's website might look slick, but what really matters is what's on their shop floor.

Key things to check:

• Machine Tool Portfolio: Do they have modern, well-maintained 5-axis CNC machines? This is often a good indicator for complex parts.

• Quality Control System: Do they have a CMM (Coordinate Measuring Machine) and other metrology tools? Ask about their inspection process and quality certifications.

• Material Experience: Have they worked with your specific material before? This can perhaps indicate a smoother process and fewer surprises.

But hey, don't just take their word for it. The real test is in the next step.

The Magic of a First Test Project

This is, in my opinion, the most underrated step. You can read all the reviews and spec sheets you want, but you won't truly know a supplier until you give them a piece of work. Starting with a smaller, less critical project is like a first date – it's a low-risk way to see if you're compatible.

What to observe during a test run:

• Communication: Are they responsive and clear? Do they ask smart questions?

• On-time Delivery: Did the parts arrive when promised?

• Final Quality: Does the finished part meet all your specified requirements and look professionally made?

This hands-on experience tells you more than a dozen sales calls ever could.

It's Not Just About the Price Tag

Let's be real, cost is a huge factor. But going with the absolute cheapest quote is often the most expensive mistake you can make. Low prices might mean corners are being cut on materials, machine maintenance, or skilled labor.

Look beyond the initial quote:

• Is their pricing transparent, or are there hidden fees?

• What is their policy on design for manufacturability (DFM) feedback? A good supplier will help you optimize your design to save costs without sacrificing quality.

• Consider the total value: reliability, communication, and technical support are part of the package you're paying for.

However, it's also true that a higher price doesn't automatically guarantee a perfect outcome every single time. The market is full of nuances.

Final Thoughts: It's a Partnership, Not Just a Purchase

Choosing a high-precision CNC machining supplier isn't a one-time transaction. You're selecting a partner who will impact your product's success. It requires a balance of technical vetting, practical testing, and building a relationship based on clear communication and mutual respect. Take your time, do your homework, and trust the data from your test projects. It's the surest path to finding a partner you can count on for the long haul.

From my own experience, the suppliers who are genuinely curious about your project and its end-use are usually the ones who go the extra mile to get it right. That's something you can't really put on a spec sheet.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque