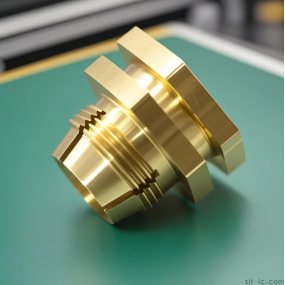

In precision manufacturing, CNC Machining non-standard screws requires specialized expertise to meet unique dimensional and functional requirements. As a leading CNC machining service provider, EMAR delivers customized screw solutions for aerospace, automotive, and industrial applications.

Challenges in Non-Standard Screw Production

Unlike standard fasteners, non-standard screws demand:

- Complex thread profiles (buttress, ACME, or custom designs)

- Precision tolerances (±.005mm achievable with our 5-axis CNC)

- Exotic materials (titanium, Inconel, or PEEK polymers)

- Unique head configurations (security, low-profile, or drive-specific)

EMAR's Advanced Manufacturing Process

Our CNC machining workflow ensures quality:

- Digital Prototyping: 3D modeling with DFM analysis

- Material Selection: 40+ metal/plastic options with certifications

- Precision Machining: Swiss-type CNC lathes for micro-screws

- Surface Treatment: Passivation, plating, or anodizing options

- Metrology: CMM inspection with full traceability

Industry-Specific Solutions

We serve critical applications including:

- Medical: Biocompatible ISO 13485 certified screws

- Automotive: High-strength fasteners for EV battery systems

- Electronics: EMI-shielding conductive screws

With ISO 9001:2015 certification and 15+ years of CNC expertise, EMAR guarantees rapid turnaround (3-7 days for prototypes) and batch production up to 500,000 units/month. Request instant quoting at www.sjt-ic.com with your CAD files.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque