As a professional CNC Machining service provider, EMAR Company understands that accurate custom quote is the first concern for procurement managers and engineers when sourcing machining services. This article will explain how we calculate CNC machining costs and what factors affect your CNC machining custom quote.

Factors Affecting CNC Machining Costs

1. Material Selection: Different metals (aluminum, steel, titanium) and plastics have varying costs

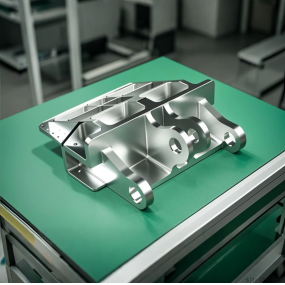

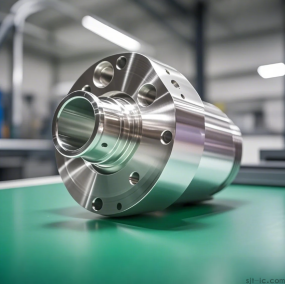

2. Part Complexity: Complex geometries require more machining time and special tooling

3. Quantity: Unit price decreases with larger production runs due to setup cost amortization

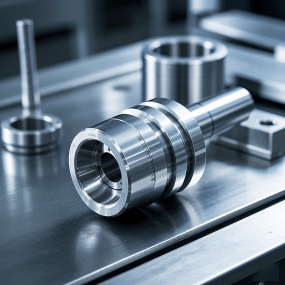

4. Tolerance Requirements: Tighter tolerances demand more precision and inspection time

5. Surface Finish: Additional finishing processes (anodizing, polishing) add to the total cost

Our Quotation Process

EMAR's 4-step quoting system ensures transparency:

1. Technical Review: Our engineers analyze your CAD files and specifications

2. Process Planning: We determine the optimal machining strategy

3. Cost Calculation: Material + machining time + secondary operations

4. Competitive Pricing: We offer market-competitive rates without compromising quality

Why Choose EMAR for Your CNC Machining Needs

- 15+ years of precision machining experience

- ISO 9001 certified quality management system

- Advanced 5-axis CNC machines for complex parts

- Fast response: Quotes within 24 hours for most projects

- One-stop solution from prototyping to mass production

For your custom CNC machining project, request a free quote today through our website https://www.sjt-ic.com/ or contact our sales team directly.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque